Metal roofing installed along the length of a roof, not across, is called lengthwise metal roofing. The long dimension of the metal roofing sheets runs from the peak of the roof down to the eaves instead of perpendicular. This provides better water runoff control on sloped roofs.

Metal roofing installed lengthwise follows the roof slope rather than going across. This provides better water runoff control. But can you overlap metal roofing lengthwise? Yes, overlapping the panels as you move down the roof is possible with exposed fastener panels. Proper installation is key for weather tightness.

Installing metal roofing lengthwise is preferred for water control. Exposed fastener metal panels allow Sliding On A Metal Roof lengthwise overlaps. The overlap degree varies by roof pitch. Proper fastening in the flat overlap space is critical for weather tightness.

Key Takeaways

- Choose the right metal roofing panel type for specific applications.

- Follow manufacturer guidelines for correct panel overlap during installation.

- Common accessories like flashing, gutters, and ridge caps enhance functionality.

- Regular maintenance, including inspections and timely repairs, is essential for longevity.

- Overlap roof sheets by at least 6 inches to prevent leaks and ensure water shedding.

Metal Roofing Installation Techniques

Metal roofing installation requires precise techniques to ensure a watertight and durable system.

Following manufacturer guidelines is crucial for proper overlap, preventing potential leaks. Professionals should handle installation to guarantee the longevity of the metal roofing.

Overlapping Course Of Roofing

| Aspect | Information |

| Importance of Overlapping | Overlap metal roofing correctly to prevent leaks. |

| Guidelines | Follow manufacturer guidelines for proper installation. Incorrect overlaps may compromise water shedding. |

| Professional Advice | Always consult with a roofing professional for guidance. |

| Panel Types and Alignment | Manufacturers provide specific instructions for each panel type. Ensure panels are aligned and overlapped as directed. |

| Watertight Roofing System | Attention to detail ensures a watertight roofing system. |

Overlap metal roofing correctly to prevent leaks. Follow manufacturer guidelines for proper installation. Incorrect overlaps may compromise water shedding. Always consult with a roofing professional for guidance.

Manufacturers provide specific instructions for each panel type. Ensure panels are aligned and overlapped as directed. Attention to detail ensures a watertight roofing system.

Adhered Method

The adhered method is a roofing installation technique where materials are bonded directly to the substrate. This approach is commonly used with roofing membranes or insulation boards. Adhesive substances ensure a secure and durable attachment, enhancing the roof’s overall performance.

In the adhered method, the key is to achieve a strong bond between the roofing material and the substrate. Proper application of adhesives and attention to surface preparation are crucial for a successful and long-lasting roofing system.

Nail Exposure To Weather

Exposing nails to the weather poses a significant risk to the integrity of your metal roofing. Rain and moisture can lead to rust and corrosion, compromising the strength of the nails over time.

To prevent issues, ensure that nails are installed properly and are adequately sealed against the elements. Regular inspections and maintenance will help identify and address any potential nail exposure, preserving the longevity and effectiveness of your metal roofing system.

Overlapping Metal Roofing

When installing metal roofing, overlapping panels is crucial. This helps keep water out and makes the roof stronger. Each panel overlaps the one next to it by about 1 to 2 inches. This prevents leaks and protects against wind.

The overlap direction depends on the roof slope. For steeper roofs, overlap from bottom to top. On flatter roofs, overlap from side to side. Proper overlapping ensures the roof stays secure and watertight for years. It’s a simple but essential step in metal roof installation.

Metal Roofing Materials And Components

Metal roofing materials consist of durable and corrosion-resistant options. Common components include metal panels, flashing, and fasteners. Proper installation with the recommended overlap is crucial for effective water shedding and preventing leaks.

Panel Types

Metal roofing materials feature diverse panel types. Standing seam panels offer a sleek, modern appearance. Corrugated panels provide strength and affordability for residential and commercial roofs.

Panel Attributes And Profiles

Metal roofing materials and components include various panel attributes and profiles. Panels come in diverse shapes and sizes, influencing the roof’s appearance and functionality. Understanding these attributes ensures the right choice for a durable and aesthetically pleasing metal roof.

Roof Deck Substrates

Now, let’s talk about roof deck substrates. These are the sturdy layers beneath your metal roof. Plywood and oriented strand board (OSB) are common choices. They provide a solid foundation for your metal roofing, ensuring a durable and reliable structure. Choose a quality roof deck substrate to support the longevity of your metal roof.

Panel Connections

Metal roofing materials include panels with various connections. These connections are crucial, ensuring the panels fit tightly together, preventing leaks. Properly aligned and securely fastened connections enhance the overall durability of the metal roofing system.

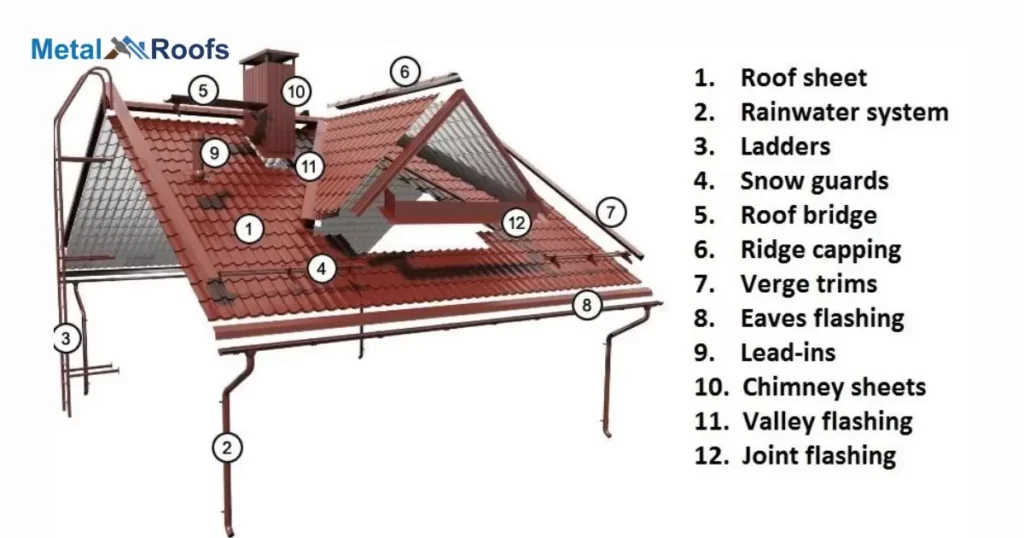

Common Roof Accessories

Metal roofing materials come with common accessories like flashing, gutters, and ridge caps. Flashing prevents leaks around openings, while gutters manage rainwater runoff efficiently. Ridge caps provide a polished finish, ensuring a complete and functional metal roofing system.

Safety Considerations In Metal Roofing Installation

Safety is paramount in metal roofing installation. Prioritize the use of proper personal protective equipment (PPE) such as gloves and safety harnesses. Adhere to safety guidelines to minimize the risk of accidents and ensure a secure working environment during the installation process.

Safety Issues

Safety during metal roofing installation is crucial. Always use proper safety gear like gloves and harnesses. Following safety guidelines ensures a secure work environment and reduces the risk of accidents.

Roofing Design

Consider the roofing design for enhanced safety. Opt for designs that facilitate secure footing and minimize risks. A well-thought-out roofing design contributes to a safer installation process.

Delivery, Receipt, Storage, And Handling Of Materials

When it comes to safety, proper handling of materials is crucial. Upon delivery, inspect materials for damage and ensure accurate quantities. Store materials securely to prevent accidents, promoting a safe and organized work environment during metal roofing installation.

Steel Roofing Overlap

Steel roofing panels overlap during installation to ensure water resistance and strength. Overlapping by 1 to 2 inches as per manufacturer’s guidelines prevents water leaks and secures panels against wind.

Proper overlap is critical for a durable roof that withstands weather conditions. Installation follows precise measurements and alignment to maintain the roof’s integrity. Each panel interlocks securely with its neighbor, forming a seamless barrier against rain and snow.

Advantages Of Overlapping Metal Roofing

Enhanced Weather Resistance: Overlapping creates a watertight seal, preventing leaks and improving the roof’s ability to withstand weather elements.

Structural Strength: The overlap adds strength to the roofing system, contributing to its durability and ability to endure harsh conditions.

Cost-Effective Installation: The straightforward installation process of overlapping metal roofing promotes efficiency, saving both time and costs for the roofing project.

Disadvantages Of Overlapping Metal Roofing

While overlapping metal roofing offers several advantages, it also has some disadvantages to consider:

Aesthetic Impact: Excessive overlapping may affect the overall appearance of the roof, leading to a less uniform and potentially unappealing look.

Weight: The additional layers from overlapping can increase the weight of the roofing system, potentially requiring structural reinforcements.

Potential for Corrosion: If not properly installed or maintained, the overlapping areas can trap moisture, leading to corrosion over time.

Careful consideration and adherence to installation guidelines can help mitigate these disadvantages and ensure a successful metal roofing system.

Metal Roofing Maintenance And Repair

Regular maintenance is crucial for the longevity of metal roofs. Inspect for loose screws or damaged panels, addressing issues promptly. Cleaning debris and checking seals will help prevent leaks and ensure optimal performance.

When repairs are needed, replace damaged panels or fix sealant gaps. Apply rust-resistant coating to maintain metal integrity. Professional inspections and timely repairs can extend the life of your metal roofing system.

Frequently Asked Questions

How much does it cost to overlap a metal roof lengthwise?

The cost of overlapping a metal roof lengthwise depends on factors like the type of metal and labor rates, varying between $1.50 to $3.50 per square foot. It’s advisable to obtain quotes from roofing contractors for accurate pricing.

How much should you overlap corrugated metal roofing?

Overlap corrugated metal roofing by at least one and a half corrugations to ensure proper water shedding and prevent leaks. Following manufacturer guidelines is crucial for the specific overlap recommendation.

How far to overlap roof sheets?

Overlap roof sheets by a minimum of 6 inches to ensure effective water shedding and prevent leaks. The exact overlap may vary based on the type of roofing material and manufacturer’s recommendations.

Conclusion

Lengthwise metal roofing follows the roof slope for good drainage. Overlapping exposed fastener panels lengthwise is possible. The amount of overlap varies based on pitch. Correct fastener placement ensures weather tightness. Annual inspection of seals maintains water control over time.

Proper lengthwise metal roofing install requires planning. Determine panel lengths, overlaps, and pitch. Calculate screw placement in flat overlaps. Use wind uplift approved fasteners. Test completed sections with spray testing before continuing. Achieve weather-tight roofs for decades with quality work.