Chimney counter flashing is metal installed where the chimney meets the roof. It sits on top of shingles and under the chimney to create a water barrier. Diverts rainwater runoff away from chimney and roof joints preventing leaks inside home.

Rain seeping into your home where the chimney meets the roof causes leaks and rot. Chimney counter flashing creates a water barrier, diverting rain away. This metal flashing sits on top of shingles, under the chimney. It seals joints vulnerable to leaks so you enjoy a dry, sound roof and home.

Properly installed chimney counter flashing creates a water-resistant barrier between the chimney and roof. Overhang on a metal roof can exacerbate the vulnerability to moisture, as water penetrates where masonry touches shingles and flows into framing where you can’t see.

Key Takeaways

- Prevent water entry around chimney and roof gap.

- Base and counter flashing made of durable metal.

- Waterproof sealant ensures a tight barrier.

- Counter flashing folds over base flashing for protection.

- Redirects water away, preventing leaks and damage.

- Professional setup recommended for lasting defense.

Purpose Of Chimney Counter Flashing In Metal Roofing

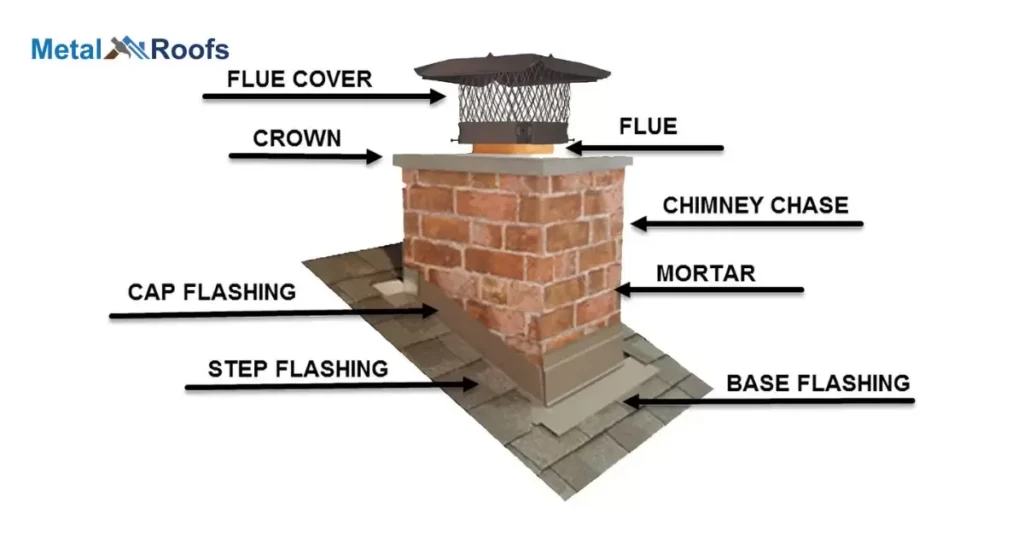

Chimney counter flashing is crucial in metal roofing. It stops water from sneaking into the gap between the chimney and the roof. At the chimney’s base, there’s base flashing. It’s metal and guides water away onto the roof. Then comes the counter flashing. It’s embedded into the chimney mortar joints and folds over the base flashing, creating a shield.

This setup keeps water out. To seal the deal, a waterproof sealant is often applied. This way, water can’t seep in and mess with your roof. It’s all about directing water away, protecting your roof and chimney from leaks. Professional installation ensures it’s done right, giving you long-lasting defense.

Install Chimney Counter Flashing On A Metal Roofing System

To secure your metal roof against leaks around the chimney, install chimney counter flashing. Start with the base flashing at the chimney’s bottom edge, extending it onto the metal roof. Use materials like aluminum or galvanized steel, ensuring durability.

This overlap shields against water infiltration, a key step in preventing potential damage. Seal the counter flashing with waterproof material to fortify the barrier and redirect water away from vulnerable areas. Professional installation guarantees long-lasting defense for your metal roofing system.

Sealing Chimney Counter Flashing On Metal Roofing

When sealing the chimney counter flashing on a metal roof, start with the base flashing. This metal layer goes at the chimney’s bottom and extends onto the roof. It guides water away. Next, embed the counter flashing into chimney mortar joints. Fold it down over the base flashing, covering its top edge.

This double-layer setup creates a protective barrier. Seal it tight with waterproof sealant for extra defense. Make sure the counter flashing overlaps the base flashing. This way, it directs water away, keeping your roof safe from leaks. Professional installation is key for long-lasting protection.

Maintenance Of Chimney Counter Flashing Important For Metal Roofing

Maintaining your chimney counter flashing is crucial, especially for metal roofing. This flashing setup, consisting of base and counter flashing, acts as a shield against water sneaking into your home. The base flashing, set at the chimney’s bottom, guides water away from trouble.

Then comes the counter flashing, wedged into the chimney mortar joints, covering the base flashing’s top edge. It’s like armor, keeping water out. To make sure it’s watertight, seal it up well. Proper installation and a keen eye on maintenance ensure your metal roof stays resilient against leaks and water damage. Take care of that flashing, and your roof will thank you for it.

Common Issues With Chimney Counter Flashing On Metal Roofing

Metal roofing paired with chimney counter flashing can face common issues. Sometimes, improper installation allows water to sneak in. If the base flashing isn’t snug against the chimney, leaks are likely. Water finding its way behind the counter flashing spells trouble too.

Overlap matters. When the counter flashing doesn’t properly cover the base flashing, it’s an open invitation for water damage. Inconsistent sealing compounds the issue. Without a tight seal, water creeps in, causing potential havoc. A solid defense, meticulous installation and precise overlap with sealed joints are key.

Common Materials Used For Counter Flashing

Common materials for counter flashing include metals like aluminum or galvanized steel. These are sturdy and effective in directing water away from chimneys. The base flashing is installed at the chimney’s bottom, extending onto the roof surface.

Counter flashing, the second layer, is then embedded into the chimney mortar joints and folded over the base flashing. This creates a protective seal, covering the top edge of the base flashing. To ensure a watertight fit, professionals often use a durable waterproof sealant.

Aluminum

Aluminum is a lightweight metal commonly used in construction. It’s often chosen for its durability and resistance to corrosion. In roofing, aluminum is frequently employed for flashing, like chimney counter flashing, providing a reliable barrier against water damage.

Copper

Copper, a versatile metal, is crucial in industries. It conducts electricity well, used in wiring. Its corrosion resistance makes it popular in roofing, and its antimicrobial properties find application in healthcare. In construction, copper offers durability and aesthetics.

Galvanized Steel

Galvanized steel is tough metal. It stops rust. Used in chimney flashing. Protects against water. Base flashing shields bottom. Counter flashing goes on top. They overlap, seal tight. Prevents leaks, keeps chimney dry.

Chimney Counter Flashing Design

Chimney counter flashing is crucial for a leak-free roof. It works in tandem with base flashing, forming a shield against water intrusion. The base flashing runs along the roof, guiding water away.

Counter flashing is embedded in chimney mortar joints, covering the base flashing’s top edge. This overlap prevents water sneaking into vulnerable points. Properly sealed with waterproof material, it fortifies the barrier. Installed correctly, it ensures water stays out, safeguarding your roof’s durability.

Chimney Counter Flashing Kit

A Chimney Counter Flashing Kit is crucial for keeping your roof leak-free. It comes with base flashing, a metal piece installed at the chimney’s bottom to steer water away. Then, there’s counter flashing, a second layer in the chimney’s mortar joints, folded down over the base to shield it. This duo forms a solid barrier against water infiltration.

Proper overlap and sealing, using waterproof sealant, are key. When installed correctly, these kits ensure water is directed away from vulnerable points, maintaining your roof’s integrity. Optimal protection, consider professional installation to safeguard against potential leaks and water damage.

Chimney Step Flashing

Chimney step flashing is vital for keeping your roof watertight. It’s metal pieces that fit between the chimney bricks and roofing material. These metal bits direct water away, preventing leaks. They work hand in hand with counter flashing.

Counter flashing, the second layer, sits on the chimney. It folds down over the step flashing, making a shield. This combo seals the gap and keeps water out. Proper installation and sealing are key for a leak-free roof. It’s a smart move for a sturdy, water-resistant roofing system.

How To Flash A Chimney On A Metal Roof?

To flash a chimney on a metal roof, start with base flashing. It goes at the chimney’s bottom, extending onto the roof. Use metal like aluminum for durability. This directs water away, a vital first step.

Embed counter flashing into chimney mortar joints. Fold it over the base flashing to shield the top edge. This overlap is key for protection. Seal with a waterproof sealant to prevent leaks. Done right, this setup ensures water won’t sneak in and compromise your roof or chimney.

Types Of Chimney Flashing

Here are short descriptions of common types of chimney flashing.

Step Flashing: L-shaped metal pieces layered along the chimney and roof, creating a stepped effect.

Continuous Flashing: Single piece of metal running along the base of the chimney, suitable for ridge or flat roofs.

Counter Flashing: Covers top edges of step flashing, embedded into chimney mortar joints for added protection.

Cap Flashing: Covers the top of the chimney, shaped like an inverted “V” or saddle to redirect water.

Kickout Flashing: Redirects water away from the intersection of a roof and sidewall.

Base Flashing: Installed at the chimney base, extending onto the roof for a watertight seal.

Drip Edge Flashing: Installed along roof edges to direct water away from vulnerable areas, including the chimney.

Flashing On Chimney

Flashing on a chimney keeps water out. It is a metal barrier. Flashing seals the joint between the roof and chimney. This prevents leaks and water damage. Common materials are steel, aluminum, and copper. Flashing needs proper installation.

First, cut a groove in the chimney. Then, bend the flashing to fit the groove. Secure it with nails or screws. Make sure it overlaps step flashing by four inches. Check for rust and damage often. Seal any gaps with caulk.

Flashing Around Chimneys

Flashing around chimneys keeps water from entering your home. It creates a barrier where the chimney meets the roof. Step flashing fits under the shingles and goes up the chimney. Counter flashing covers the step flashing. Both work together to stop leaks.

Metal like steel or copper makes strong flashing. Installers bend it to fit snugly. They secure it with nails or screws. Regular checks help catch rust or damage. Fix issues quickly to keep your roof safe. Proper flashing means fewer roof repairs.

Frequently Asked Questions

What is counter flashing a chimney detail?

Chimney counter flashing is a water-blocking duo. Base flashing sends water away, and counter flashing caps it, sealed tight. Overlap is key to keeping the roof dry and free from leaks, a simple but crucial detail.

What is the purpose of chimney flashing?

Chimney flashing keeps water out. It’s metal installed on the roof. Stops leaks, protects your home. Base flashing at bottom, counter flashing on chimney. They overlap, sealing with waterproof stuff. Simple but crucial for a dry home.

What is the best flashing for a chimney?

Metal flashing offers prime chimney protection. Install base flashing at the chimney base, extending onto the roof. Embed counter flashing in chimney mortar, fold over the base, seal tightly, ensure overlap for leak prevention.

Conclusion

Chimney counter flashing is an important roofing element. It creates a water barrier between the chimney and shingles. This metal flashing diverts rainwater away from vulnerable joints. It prevents leaks, decay, and structural damage. Don’t forget this step when installing or replacing your chimney.

Correctly installing chimney counter flashing takes skill. Work with an experienced roofer or masonry pro. They will ensure proper placement and function. This protects your chimney, roof, and home from moisture damage. It preserves structural integrity. Your biggest investment deserves quality craftsmanship.