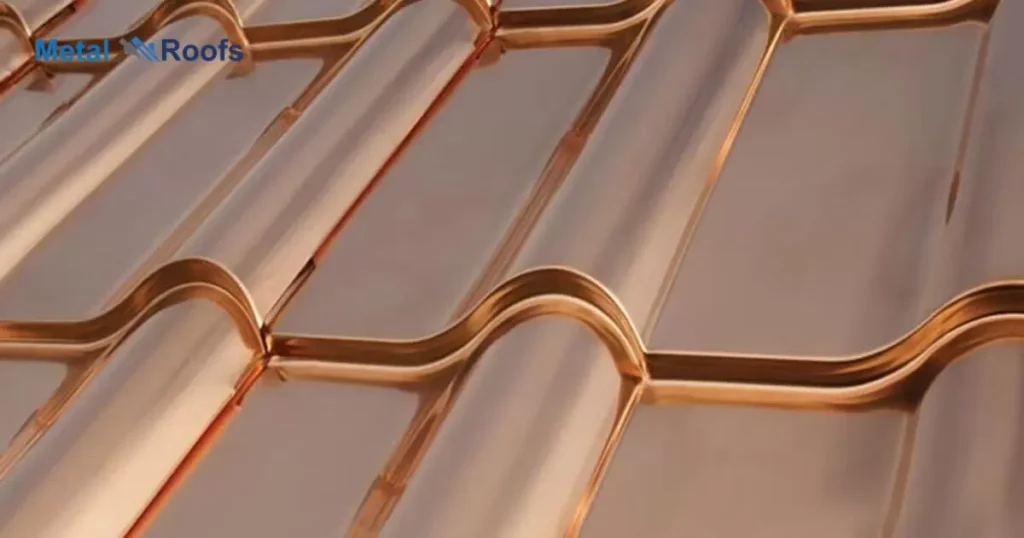

Closure strips are narrow metal strips used to join standing seam metal roofing panels together and seal the joints, preventing water leakage; they interlock or snap together over the raised seams where roofing panels meet.

Metal roofs require proper sealing to prevent leaks. Closure strips snap together over raised seams on standing seam metal panels. Do I need closure strips for metal roofing? Yes, these narrow metal strips join panels, seal joints between them, and stop rain and snow from penetrating your roof.

Closure strips seal metal roofing panels. They snap together over raised seams, interlocking panels. This prevents water leaks where panels join. Quality closure strips are narrow metal strips custom-fit to your roof’s panels. They seal joints, keeping water out of your home. Proper installation is key.

Key Takeaways

- Closure strips are essential for sealing gaps in metal roofing.

- They prevent water, debris, and pests from entering.

- Closure strips aid ventilation, reducing moisture buildup and rust.

- They provide structural support, preventing bending and warping.

- Closure strips also dampen noise from temperature fluctuations.

Strips Important for Metal Roofing

Closure strips are crucial for metal roofing. They seal gaps and keep out water and debris. These strips also provide ventilation, preventing moisture buildup.

They support the roofing panels, enhancing durability. Replace Flashing During Roof Replacement Noise reduction is another benefit of using closure strips. Overall, they’re essential for a reliable metal roofing system.

Closure Strips Work with Metal Roofing

Closure strips are like silent guardians for metal roofing. They snugly fit between panels, sealing out rain, wind, and pests. Without them, your roof could be vulnerable to leaks and damage. These strips ensure a tight, weather-resistant seal along the edges and ridges.

Closure strips help maintain proper ventilation beneath the metal. They allow air to circulate, preventing moisture buildup. This ventilation helps to prevent rust and mold, keeping your roof in top condition.

Types of Closure Strips for Metal Roofing

Closure strips for metal roofing are essential components that help seal gaps and prevent leaks in the roofing system. There are several types of closure strips available, each designed for specific applications and roofing profiles. Here are some common types:

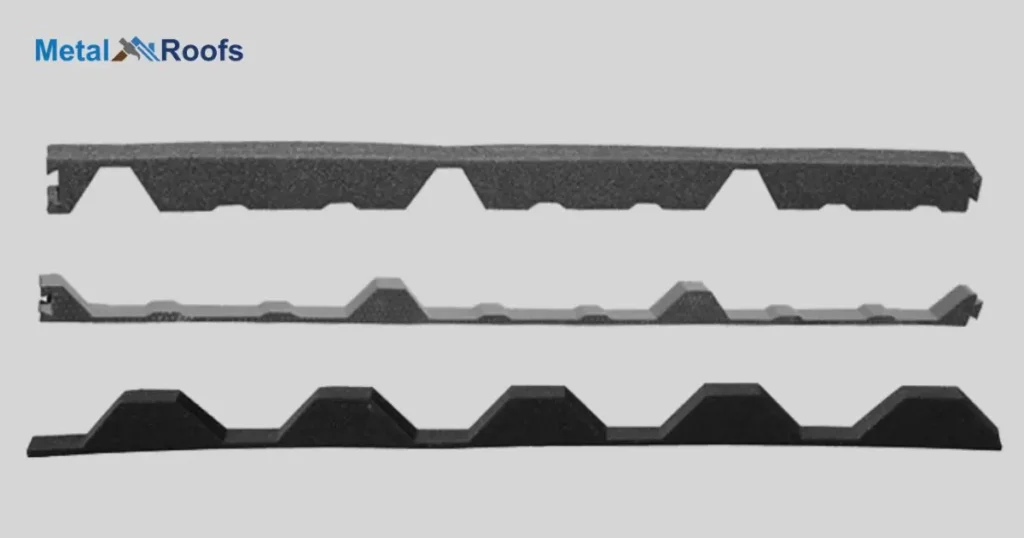

Foam Closure Strips: These closure strips are made of foam material, such as polyethylene or neoprene. They come in various shapes and sizes to fit different roof profiles. Foam closure strips provide a flexible and effective seal against weather elements and insects.

Butyl Rubber Closure Strips: Butyl rubber closure strips offer excellent sealing properties and adhere well to metal roofing panels. They are durable and resistant to temperature changes, making them suitable for long-term use in harsh weather conditions.

Vented Closure Strips: Vented closure strips are designed with perforations or gaps to allow airflow under the metal roofing panels. They help prevent moisture buildup and improve ventilation in the roof space, which can reduce the risk of condensation and mold growth.

Ribbed Closure Strips: Ribbed closure strips are specifically designed to match the rib profile of certain metal roofing panels. They provide a snug fit between the ribs, ensuring a tight seal and preventing water penetration.

Self-Adhesive Closure Strips: These closure strips come with a self-adhesive backing for easy installation. They adhere directly to the underside of the metal roofing panels, creating a secure seal without the need for additional fasteners.

Closures for Ridge and Eave: These closure strips are tailored for sealing the gaps at the ridge and eave of the roof. They help prevent wind-driven rain and debris from entering the roof structure while maintaining proper ventilation.

Corrugated Closure Strips: Corrugated closure strips are designed specifically for corrugated metal roofing panels. They match the corrugation pattern of the panels, providing a tight seal and preventing water intrusion.

Proper installation of closure strips is crucial for ensuring the longevity and performance of the metal roofing system.

Install Closure Strips on Metal Roofing

Installing closure strips on metal roofing is an essential step to ensure a watertight and secure roofing system. Here’s a general guide on how to install closure strips:

Materials Needed:

- Closure strips (choose the appropriate type for your roofing system)

- Measuring tape

- Utility knife or scissors

- Caulking gun (if using adhesive-backed closure strips)

- Fasteners (if required)

Steps:

Prepare the Roof: Ensure that the metal roofing panels are clean and free from debris. Inspect the roof for any damage or irregularities that may affect the installation of closure strips.

Measure and Cut: Measure the length of the ridge, eave, or panel where the closure strips will be installed. Use a measuring tape to determine the required length of closure strips. If necessary, use a utility knife or scissors to cut the closure strips to the appropriate size.

Position the Closure Strips: Place the closure strips along the ridge, eave, or between the metal roofing panels, depending on the application. Ensure that the closure strips fit snugly and cover any gaps between the roofing panels.

Fasten (if required): Some closure strips may require fasteners to secure them in place. If needed, use appropriate fasteners such as screws or nails to attach the closure strips to the roof structure. Follow the manufacturer’s recommendations for spacing and placement of fasteners.

Adhere (if using adhesive-backed strips): If using self-adhesive closure strips, remove the protective backing to expose the adhesive surface. Press the closure strips firmly onto the underside of the metal roofing panels, ensuring full contact and adhesion.

Seal Joints (if necessary): If there are any joints or seams where closure strips meet, use caulking or sealant to provide additional waterproofing and prevent water infiltration.

Inspect and Test: Once all closure strips are installed, visually inspect the roof to ensure that they are properly positioned and securely attached. Test the integrity of the closure strips by running water over the roof and checking for any leaks or gaps.

Final Touches: Trim any excess material from the closure strips if needed, and make any final adjustments to ensure a neat and tidy installation.

By following these steps, you can effectively install closure strips on metal roofing to create a weather-resistant and durable roofing system. If you’re unsure about any aspect of the installation process, consult the manufacturer’s instructions or seek guidance from a professional roofer.

Common Mistakes to Avoid When Installing Strips on Metal Roofing

| Mistake | Description |

| Improper Alignment | Leads to uneven appearance and potential water leakage. |

| Inadequate Fastening | Can cause noise, leaks, and structural issues over time. |

| Lack of Weatherproofing | Allows water infiltration, leading to rust and damage. |

| Ignoring Manufacturer Guidelines | Compromises integrity and voids warranties. |

| Poor Sealant Application | Results in water ingress and interior damage. |

| Overlooking Expansion and Contraction Planning | Causes buckling and damage over time. |

| Insufficient Underlayment Protection | Leads to moisture buildup and premature deterioration. |

| Improper Panel Handling and Cutting | Damages appearance, performance, and integrity. |

When installing strips on metal roofing, avoid skipping closure strips. They’re crucial for weatherproofing and structural support. Without them, you risk water leaks and structural damage.

Another common mistake is using the wrong type of closure strip. Ensure you choose the appropriate material and size for your roofing system. Using incorrect closure strips can lead to inadequate sealing and ventilation, causing problems down the line.

Choose the Right Closure Strips for Your Metal Roofing

When selecting closure strips for your metal roofing, ensure they match the specific profile and design of your panels. Proper fitting is crucial for effective weatherproofing and ventilation. Incorrect closure strips may lead to leaks and airflow issues, compromising the integrity of your roof.

Consider the material of the closure strips; options include foam, rubber, and neoprene. Each material offers unique advantages, such as flexibility, durability, and resistance to weathering. Choose the one that best suits your climate and roofing requirements for optimal performance and longevity.

Benefits of Using Closure Strips for Metal Roofing

- Closure strips ensure a snug fit between panels, preventing water, debris, and pests from entering, thus maintaining the roof’s integrity.

- They facilitate proper airflow beneath the panels, preventing moisture buildup and reducing the risk of rust and mold growth.

- Closure strips provide additional support to the roofing panels, distributing weight evenly and minimizing the risk of bending or warping.

- They help dampen noise from panel expansion and contraction, making the roof quieter and more comfortable.

- By enhancing weather resistance and structural integrity, closure strips contribute to the longevity of the metal roofing system.

Maintain Closure Strips on Metal Roofing

Maintaining closure strips on metal roofing is crucial for long-term performance. These strips seal gaps, keeping out water, debris, and pests. Without them, your roof could suffer from leaks and damage. Remember, proper ventilation is key to preventing moisture buildup and mold growth.

Regular inspection and replacement of closure strips ensure your roof stays in top condition. Don’t overlook this simple yet important task. By keeping closure strips intact, you’re protecting your investment and ensuring your metal roof lasts for years to come.

How to Inspect Closure Strips on Metal Roofing?

Inspecting closure strips on metal roofing is vital for roof integrity. Start by visually checking for wear, damage, or gaps. Ensure alignment along edges and seams, and confirm compatibility with the roofing material. Regular inspection prevents costly repairs and extends roof life.

Foam Closure Strips For Metal Roofing

Foam closure strips are crucial for metal roofing installations. They provide a tight seal, keeping out water, debris, and pests. Plus, they help with ventilation, preventing moisture buildup and reducing the risk of rust or mold.

These strips also offer structural support, ensuring the roofing panels stay in place and resist bending or warping over time. Overall, foam closure strips are essential for a durable and reliable metal roofing system.

Frequently Asked Questions

What is a closure on a metal roof?

A closure on a metal roof is a sealing component used to fill gaps and prevent water infiltration. It ensures a tight and weatherproof seal between roofing panels and other structures.

Do you need trim for the metal roof?

Yes, trim is necessary for a metal roof to ensure proper installation and weatherproofing.

Do you need to strap a metal roof?

Yes, strapping a metal roof is typically recommended for structural support and stability.

Conclusion

Closure strips are important metal roofing components. They seal the joints between roofing panels. Quality strips properly fitted and installed prevent leaks. Consider closure strips when planning your metal roof. Correctly sealing panels avoids future issues.

Installing closure strips takes precision. Ensure you order the right size and style. Carefully snap them together over roof seams per manufacturer guidelines. Apply pressure so the seal is air and watertight. Check for gaps where water could enter. Annual inspections ensure your strips and roof remain leak free.