Foamular 150 and 250 are types of extruded polystyrene insulation board. Foamular 150 has an R-value of 5 per inch while Foamular 250 has an R-value of 8 per inch, meaning 250 provides more insulation per inch. Both are lightweight, water resistant rigid foam boards used for insulation in walls, roofs and foundations to improve energy efficiency.

Want better insulation for your next project? Foamular 150 and 250 are extruded polystyrene boards that differ in efficiency. Foamular 250 has a higher R-value, meaning better insulation per inch. But Foamular 150 costs less while still providing good thermal resistance. Choose based on your climate, budget and how much insulation you need.

Foamular insulation boards come in 150 and 250 types, rating thermal resistance. 250 insulates better per inch with R-8 but costs more. R-5 Foamular 150 still improves energy efficiency for less. Pick type by climate and budget needs.

Key Takeaways

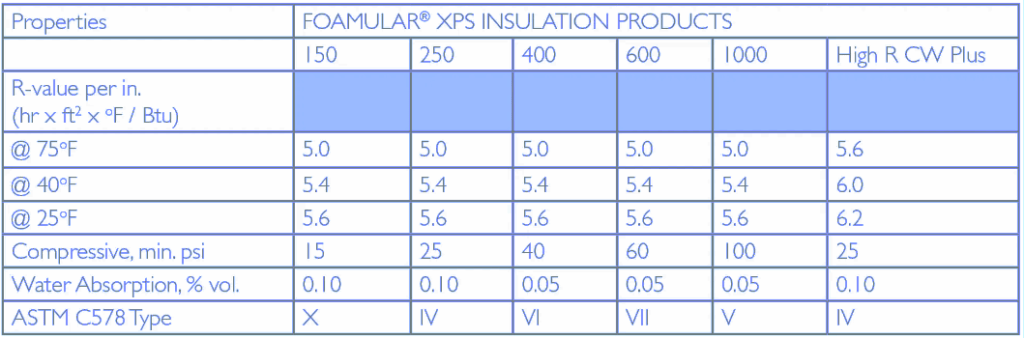

- Compressive Strength: FOAMULAR 150 has ~15 psi, while FOAMULAR 250 boasts ~25 psi.

- Application: 150 suits standard loads, 250 for heavier ones.

- Cost: 250 is pricier due to higher performance.

- R-Value: Both offer ~R-5 per inch thickness.

- Moisture Resistance: Both excel in keeping buildings dry.

What Is FOAMULAR Xps Insulation?

| Feature | FOAMULAR 150 | FOAMULAR 250 |

| Compressive Strength | 15 psi | 25 psi |

| Application | Standard loads | Heavier loads |

| Cost | Lower cost | Higher cost |

| R-Value | R-5 per inch thickness | R-5 per inch thickness |

| Moisture Resistance | Excellent moisture resistance | Excellent moisture resistance |

| Thermal Insulation | High R-value per inch for energy efficiency | Excellent thermal resistance |

| Lightweight | Yes | Yes |

| Fire Resistance | Yes | Yes |

| Dimensional Stability | Maintains shape over time | Maintains shape over time |

| Compatibility | Versatile, suitable for various applications | Suitable for various applications |

| Longevity | Durable insulation performance | Durable insulation performance |

| Environmental Impact | Made with recycled materials | Made with recycled materials |

FOAMULAR XPS insulation is a type of rigid foam board made by Owens Corning. It’s used to insulate buildings, keeping them warm in winter and cool in summer. FOAMULAR comes in different grades like 150 and 250, with varying compressive strengths.

Incorporating a drip edge for a metal roof with UFOAMULAR XPS insulation boards ensures effective water management, preventing leaks and water damage.

FOAMULAR 150 Vs 250: What’s The Difference?

FOAMULAR 150 and FOAMULAR 250 are insulation boards by Owens Corning. They differ in compressive strength: 150 is 15 psi, 250 is 25 psi. Both have similar R-values around 5 per inch. 150 suits lighter loads, while 250 is for heavier ones. Cost-wise, 250 tends to be pricier. Both are easily available for construction needs.

FOAMULAR 150: Features and Benefits for Metal Roofing

Thermal Insulation: High R-value per inch for energy efficiency.

Moisture Resistance: Prevents mold, rot, and degradation.

Lightweight: Easy to handle and install, reducing labor costs.

High Compressive Strength: Withstands weight and pressure of metal roofing.

Fire Resistance: Provides additional safety in case of fire.

Dimensional Stability: Maintains shape over time for consistent performance.

Compatibility: Works effectively with metal roofing systems.

Longevity: Offers durable insulation performance with proper maintenance.

Environmentally Friendly: Made with recycled materials, reducing environmental impact.

FOAMULAR 250: Advantages in Metal Roofing Applications

FOAMULAR 250 is another type of rigid foam insulation board manufactured by Owens Corning. When used in metal roofing applications, it offers several advantages:

Superior Thermal Insulation: FOAMULAR 250 provides excellent thermal resistance, effectively regulating interior temperatures and reducing energy consumption associated with heating and cooling.

Moisture Resistance: Its moisture-resistant properties help prevent issues like mold growth and structural damage, maintaining the integrity and longevity of the roofing system.

Strength and Durability: With high compressive strength, They can withstand the weight and pressure of metal roofing materials, ensuring long-term structural stability.

Fire Resistance: The material typically possesses fire-retardant properties, enhancing the safety of the roofing system and the building as a whole.

Dimensional Stability: It maintains its shape and dimensions over time, even under varying environmental conditions, ensuring consistent performance and thermal efficiency.

Ease of Installation: It is lightweight and easy to handle, facilitating swift and straightforward installation, which can help reduce labor costs and project timelines.

Compatibility with Metal Roofing Systems: Designed to work seamlessly with various metal roofing materials, ensuring proper integration and optimal performance of the entire roofing system.

Environmental Considerations: Owens Corning manufactures FOAMULAR 250 with a commitment to sustainability, incorporating recycled materials and reducing environmental impact.

Overall, FOAMULAR 250 offers a combination of thermal efficiency, durability, moisture resistance, and ease of installation, making it an excellent choice for metal roofing applications where energy efficiency and long-term performance are paramount.

FOAMULAR 150 Installation

FOAMULAR 150 is easy to install. Just measure and cut. Fit snugly in the space. Seal edges tightly. Use adhesive for secure attachment. Ensure proper ventilation. Keep away from open flames. Follow safety guidelines.

Corning Foamular 150 Vs 250

Corning Foamular 150 and 250 differ in compressive strength. Foamular 150 has 15 psi strength, while Foamular 250 has 25 psi. The higher strength of Foamular 250 suits heavier loads.

Foamular 150 is more versatile, used in various applications. Foamular 250 costs more due to its stronger performance. Both types offer excellent thermal resistance, typically an R-value of 5 per inch.

Moisture Resistance of FOAMULAR Insulation

FOAMULAR insulation stands strong against moisture. It shields buildings from dampness, safeguarding against potential damage. Its robust structure keeps water at bay, ensuring long-lasting protection for your property.

With FOAMULAR, worries about mold and mildew are a thing of the past. Its moisture resistance prevents these harmful elements from thriving. Enjoy peace of mind knowing your insulation can handle whatever the weather throws its way.

Frequently Asked Questions

What is Foamular 250 used for?

FOAMULAR 250 is primarily used for applications requiring higher compressive strength, such as heavy-duty residential, commercial, or industrial projects.

What is Foamular 150 used for?

FOAMULAR 150 is commonly used for insulation in walls, roofs, and foundations to provide thermal protection and moisture resistance.

What is equivalent to Foamular 250?

FOAMULAR 250 is equivalent to insulation boards with a compressive strength of approximately 25 psi.

Conclusion

Foamular insulation boards provide energy efficiency. The 150 type has an R-value of 5 per inch. The 250 type rates even better at R-8 per inch thickness. Both resist moisture while staying lightweight.

Decide which Foamular works best for your specific project. In cold climates, choose 250 for maximum insulation if budget allows. In warmer zones, an affordable 150 still improves thermal resistance. Evaluate climate and cost needs. Then pick the Foamular to optimize walls, roofs or foundations.