Metal roofing panels need screws spaced 12-18 inches apart in the flat of the panel and 6-12 inches apart in the ribs to securely fasten the roofing to the decking below proper screw spacing prevents leakage and wind damage while allowing for expansion and contraction of the panels.

How far apart should screws be on metal roof ? It’s a common query. Well, the key is spacing. Properly spaced screws ensure durability and weather resistance. Let’s dive into the specifics your metal roof’s longevity might just depend on it.

The spacing between roofing screws, including consideration for Chimney Counter Flashing, significantly impacts performance. Incorrect spacing can lead to issues such as panel detachment in high winds or leaks due to inadequate sealing.

Key Takeaway

- Space 12-18″ apart across panels

- Space 6-12″ apart along ribs

- Prevents wind damage and leaks

- Allows for expansion and contraction

- Follow manufacturer guidelines

- Consider roof pitch and climate

Importance Of Proper Screw Placement On Metal Roofs

| Key Aspect | Importance |

|---|---|

| Structural Integrity | Proper screw placement ensures the stability and strength of the roof. |

| Leak Prevention | Accurate placement helps in creating a watertight seal, preventing leaks. |

| Wind Resistance | Correct screw positioning enhances the roof’s resistance to strong winds. |

| Longevity of Roof | Well-placed screws contribute to the overall durability of the metal roof. |

| Aesthetic Considerations | Precise placement maintains a neat appearance and enhances curb appeal. |

Proper screw placement on metal roofs is crucial. It ensures the roof stays put during harsh weather. The manufacturer’s guide for the right screw spacing, is usually 12 to 24 inches along seams. Pay attention to edges, needing tighter spacing for added wind resistance.

Your local building codes also matter; check them. A well-placed screw grid using metal roof screws on rib or flat keeps your roof sturdy, meeting both safety standards and the product’s specifications. Trust the guidelines, avoid shortcuts, and consult experts if needed.

Factors Affecting Screw Spacing, Such As Roof Type, Material, And Climate

When installing a metal roof, the screw spacing is influenced by crucial factors. The type of roof and the chosen material play a key role. Different roofs have different needs steep slopes might demand closer screws. It’s a smart move to check local building codes since they often set the rules.

Climate is another player in this game. Areas with heavy wind or snow might need tighter screws for extra strength. Manufacturers have a say too always stick to their guidelines. Following these factors ensures a secure metal roof, ready for whatever weather comes its way.

What’s The Standard Distance Between Screws On Metal Roofing Panels?

When installing metal roofing panels, follow the manufacturer’s guidelines for screw placement. Check local codes for any specific rules in your area. Typically, screws are spaced 12 to 24 inches apart along the seams. Pay attention to the roof slope and design steeper slopes may need closer spacing.

The edges of panels usually have tighter screw placement for better wind resistance. Consider environmental factors like high winds or heavy snow, adjusting spacing accordingly. Always consult professionals if unsure, ensuring a secure and compliant installation.

Exploring The Formula For Determining The Optimal Screw Spacing

When deciding how far apart to place screws on a metal roof, start by checking the manufacturer’s guidelines. They provide the crucial details tailored to your specific roofing material. Local building codes play a role, so consult them to ensure compliance.

Consider the slope and design of your roof, adjusting screw spacing accordingly. Steeper slopes might need closer screws, especially in areas prone to strong winds and heavy rainfall. Environmental factors matter too regions with harsh weather may require tighter screw spacing for added stability.

Factoring In The Roof’s Slope, Wind Resistance, And Other Considerations

When installing a metal roof, follow the manufacturer’s advice on screw placement. Check local building codes for any specific rules in your area. Adjust screw spacing based on the roof’s slope and design. Steeper slopes may need closer screw placement, especially in windy or rainy regions.

Consider the type of substrate and underlayment used, adhering to guidelines. Factor in environmental conditions, like high winds or heavy snow loads. These steps to ensure a secure and resilient metal roof installation.

What Happens If Screws On Metal Roofing Are Too Close Or Too Far Apart?

When metal roofing screws are too close, it can lead to problems. Water may find its way in, causing leaks. Also, too-close screws can weaken the roof structure. High wind areas might suffer more.

On the flip side, screws too far apart aren’t great either. This leaves gaps, making the roof less sturdy. It’s like a chain missing links. In harsh your roof needs all the support it can get. So, follow the manufacturer’s guide and local codes. Get the balance right for a strong, leak-free metal roof.

Explaining The Risks Of Leaks, Structural Damage, And Reduced Roof Lifespan

When a metal roof has too few screws or incorrect spacing, it opens the door to leaks. These leaks can quietly damage your structure, leading to expensive fixes down the road. Water finds a way, and without proper screw placement, it becomes an unwelcome guest.

Structural damage is a domino effect. Those leaks weaken the very bones of your roof. It’s like a slow game of Jenga, with your roof’s integrity at stake. Leaks, more damage until it’s not just a roof problem but a home problem. Plus, this structural dance shortens the lifespan of your roof.

Discussing The Consequences Of Improper Screw Placement

Improper screw placement on a metal roof can lead to serious consequences. If screws are spaced too far apart, it compromises the roof’s stability, making it vulnerable to wind damage. This oversight may also allow water infiltration, causing leaks and potential structural issues.

Always follow the manufacturer’s recommendations for screw spacing to ensure a secure and weather-resistant installation. Local building codes play a crucial role too violating them by neglecting proper screw placement can result in costly repairs and code compliance issues. Don’t overlook the significance of this detail.

Providing Best Practices For Screw Installation

When installing a metal roof, start by checking the manufacturer’s guide it’s your roadmap. Follow their screw spacing recommendations they know their product best. Local codes matter too, so get familiar with them. Adjust your spacing based on roof slope and design steep roofs need closer screws.

The edges and seams may have different spacing needs. Lastly, consider your local weather harsh conditions might call for tighter screws. Stick to these best practices for a solid, weather-resistant metal roof installation.

Addressing Common Mistakes And How To Avoid Them

Common mistakes can trip us up, so let’s tackle them head-on. First up, overlooking instructions it happens. Take a breath, read them twice. Next, rushing in without a plan a classic misstep. Slow down, sketch it out, then dive in.

Another pitfall is neglecting proofreading. Typos sneak in give your work a once-over. Lastly, going it alone can be isolating. Don’t hesitate to ask for help teamwork makes the dream work. Keep these slip-ups in check, and success is yours.

Metal Roofing Screw Calculator

Calculating metal roofing screws is a breeze with our user-friendly calculator. Measure your roof’s length and width, then input the data into the tool. It instantly computes the number of screws needed for your project, saving you time and effort.

No need for complex formulas or confusing steps our calculator simplifies the process. Just enter the measurements, and you get the precise screw count. It’s a handy tool for anyone tackling a metal roofing project, ensuring you have the right amount of screws without the guesswork. Try it now for a seamless roofing experience.

Screw Spacing For Corrugated Metal Roofing

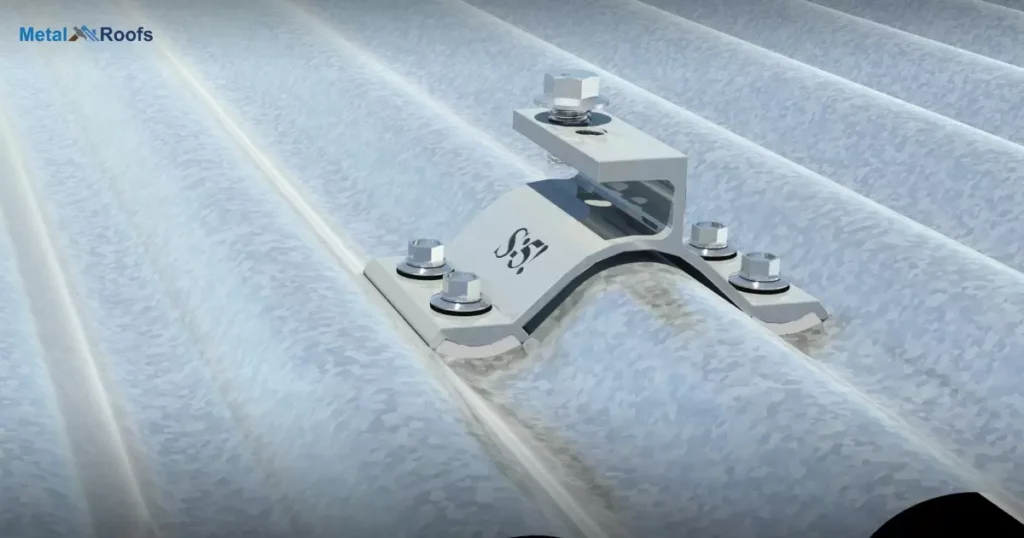

When installing corrugated metal roofing, proper screw spacing is crucial. To prevent leaks and ensure stability, place screws at every corrugation. This means securing them in the valleys, not just on the ridges.

Maintaining a consistent spacing of 24 inches between screws is recommended. This provides ample support and prevents the metal sheets from warping or buckling. Following these guidelines ensures a durable and watertight corrugated metal roof.

Metal Roof Screw Pattern

When installing a metal roof, you need to follow a specific screw pattern. Start by placing screws 12 to 18 inches apart along the edges. This helps secure the perimeter of the roof. For the middle sections, place screws about 24 inches apart. This spacing keeps the roof panels tight and secure.

Make sure each screw goes through the high point of the corrugation. This prevents leaks and ensures a snug fit. Always use screws with rubber washers to create a waterproof seal. Check with the manufacturer for any special instructions. Following these steps will help you install a sturdy and leak-free metal roof.

Steel Roof Screw Spacing

When installing a steel roof, screw spacing is key. Place screws 12 to 18 inches apart along the edges. This keeps the edges tight and secure. In the middle, space screws 24 inches apart. This allows the roof to expand and contract.

Always follow the manufacturer’s guidelines. Different steel roofing materials may need different spacing. Check the instructions before you start. Proper spacing helps prevent leaks and ensures a long-lasting roof.

Metal Roof Fastener Spacing

For a metal roof, you need to space screws properly. Along the edges, place screws 12 to 18 inches apart. In the middle of the roof, space them 24 inches apart. This keeps the roof secure and allows for movement.

Always check the manufacturer’s guidelines. Different materials might need different spacing. Following these rules helps your roof last longer. It also prevents leaks and damage. Proper screw spacing is key to a strong metal roof.

Frequently Asked Questions

What Is The Spacing For Metal Screws On A Roof?

Space metal screws on a roof 12 to 24 inches apart for stability and to avoid future problems like warping or buckling.

Where Is The Proper Place To Put Screws On A Metal Roof?

When dealing with a metal roof, place screws strategically at the ridge and eave. The topmost part ensures tight sealing, preventing leaks. Secure attachment, space screws evenly along the edges.

How Tight Should Screws Be On A Metal Roof?

Tighten metal roof screws snugly but avoid overdoing it. A hand tool and stop when you feel resistance for a secure fit without causing damage.

Conclusion

Proper screw spacing is vital. It prevents wind damage. It prevents leaks. It allows for expansion. Space screws 12-18 inches apart across panels. Space 6-12 inches apart along ribs. Use gasketed screws. Tighten them correctly. Don’t overdrive or underdrive. This ensures a secure roof.

Installing a metal roof is easy. But spacing is key. Now you know the rules. Space screws by area and location. Go by the expert recommendations. This prevents future issues. It leads to performance and longevity. You protect your investment. You reduce maintenance. You add roof value. You boost curb appeal.