Cut metal roofing with a circular saw. Use the right blade for metal. Mark your cut line clearly. Wear safety gear. Clamp the sheet down tight. Go slow and steady. Keep the saw straight. Clean up metal shavings after. This method works well for DIY jobs.

Need to cut metal roofing? A circular saw can do the job. It’s quick and easy with the right steps. You don’t need fancy tools. Just follow some key tips. Learn how to cut metal roofing with a circular saw. We’ll show you the safe way. Get clean cuts every time.

Cutting metal roofing can seem tough, but a circular saw makes it simple. With proper prep and care, you’ll succeed. This guide covers safety, technique, and the pitch does a metal roof need.

Key Takeaways

- Wear gloves, safety glasses, ear protection, and long sleeves.

- Clear the area of flammable materials.

- Use carbide-tipped or diamond blades for metal.

- Avoid wood-cutting blades.

- Measure and mark the metal accurately before cutting.

Safety Measures When Cutting Metal Roofing

When cutting metal roofing, wear safety gear. Use gloves, safety glasses, and ear protection. Wear long sleeves to protect your skin. Clear the work area of any obstacles. Ensure the workspace is well-ventilated. Keep a first aid kit nearby.

Secure the metal sheet firmly. Use clamps to prevent movement. Hold the saw with both hands. Start the saw before it touches the metal. Cut slowly and steadily. After cutting, handle the metal carefully to avoid sharp edges. Clean up all metal shavings to prevent injuries.

Choosing the Right Cutting Tools

Choosing the right cutting tools is crucial for safety and precision. Use a circular saw with a metal-cutting blade. Make sure your blade matches the type of metal you cut. Wear safety gear and secure your metal sheet before starting. Handle tools and metal pieces carefully to avoid injuries.

Manual Metal Shears

When selecting cutting tools, consider manual metal shears. They are versatile and straightforward. Perfect for cutting thin metal sheets. Ensure a firm grip and steady hand while using them.

Aviation Snips or Compound Snips

When selecting cutting tools like aviation snips or compound snips for metalwork, consider their specific uses. Aviation snips are designed for straight lines and curves in thin sheet metal, color-coded for different cuts.

Electric Shears and Nibblers

When choosing the right cutting tools like electric shears and nibblers, consider the type of material you’ll be cutting. Electric shears are ideal for straight cuts on lighter metals like aluminum. Nibblers excel at cutting intricate shapes and thicker metals.

Step-by-Step Guide to Cutting Metal Roofing Panels

Measure and mark the metal panel where you need to cut. Wear safety gear like gloves and goggles. Secure the panel with clamps on a stable surface. Use a circular saw with a metal-cutting blade. Start the saw before touching the metal. Cut slowly along the marked line. Handle the cut edges carefully. Clean up metal shavings when done.

Measure and Mark

To begin cutting metal roofing panels, start by measuring and marking the area where you intend to cut. Use a measuring tape and a marker for accuracy. Ensure your markings are clear and precise to guide your saw. This step sets the foundation for a clean and controlled cutting process.

Secure the Sheet

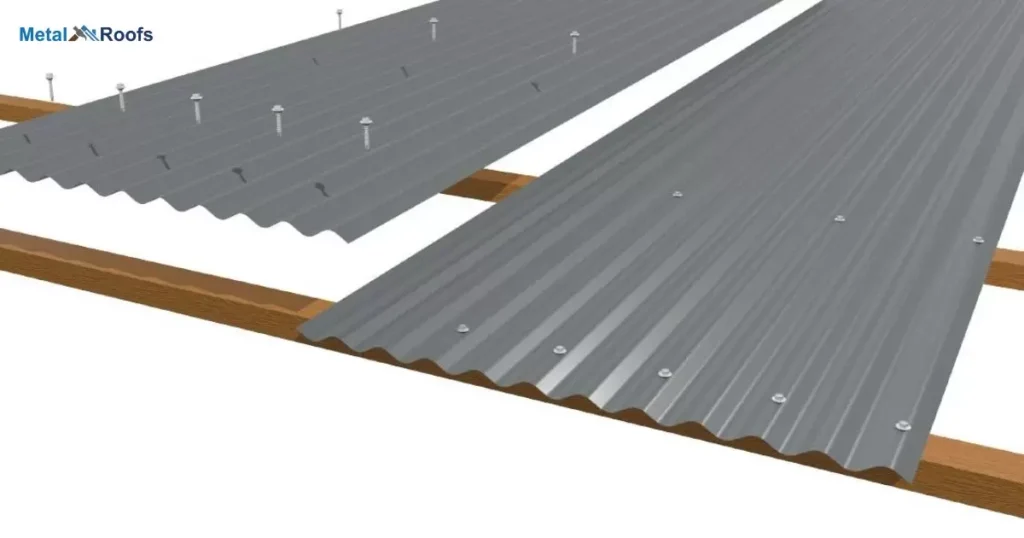

Secure the metal sheet firmly using clamps or have someone hold it steady. This prevents movement during cutting. Ensure the sheet is on a stable surface like sawhorses or a table. This stability helps maintain control while using the circular saw with a metal-cutting blade.

Cutting Techniques

To cut metal roofing panels, use a circular saw with a metal-cutting blade. Start the saw before touching the metal to prevent binding. Cut slowly and steadily along the marked line. Ensure a consistent speed to maintain control and achieve a clean cut.

Finishing Touches

After cutting, smooth any rough edges using a file or sandpaper. This helps prevent injuries and ensures a clean finish. Dispose of metal shavings properly to avoid accidents. Double-check the work area for cleanliness and safety before finishing up.

Tips for Cutting Specialty Metal Roofing

Cutting specialty metal roofing requires careful planning and the right tools to ensure precision and safety. Here are some tips to help you effectively cut specialty metal roofing:

Tools You May Need

Tin Snips: Ideal for cutting small sections and making intricate cuts.

Electric Shears: Good for longer cuts and thicker metal roofing.

Circular Saw with Metal Cutting Blade: Suitable for straight, long cuts on thicker metal panels.

Nibblers: Effective for cutting curves and intricate shapes in metal sheets.

Jigsaw with Metal Blade: Useful for detailed and curved cuts.

Angle Grinder with Cut-Off Wheel: Works for small, precise cuts and trimming.

Protective Gear: Safety goggles, gloves, ear protection, and long sleeves.

Preparation Tips

Measure Accurately: Double-check your measurements to ensure precise cuts. Use a straightedge or a chalk line for marking.

Mark Your Cuts: Use a marker or a scriber to outline the area to be cut. Ensure the line is visible.

Secure the Metal: Clamp the metal sheet securely to prevent movement while cutting.

Cutting Tips

Choose the Right Tool: Match the tool to the type of cut and the thickness of the metal. For example, tin snips for small, intricate cuts, and a circular saw for long, straight cuts.

Cut Slowly: Avoid rushing the cut to prevent mistakes and ensure a clean edge. Let the tool do the work.

Start with a Pilot Hole: If using a jigsaw or nibbler for interior cuts, drill a pilot hole to make it easier to start the cut.

Protect the Coating: If the metal roofing is coated, use tools and techniques that minimize damage to the protective layer.

Deburr the Edges: After cutting, use a deburring tool or sandpaper to smooth the edges and remove any sharp burrs.

Safety Tips

Wear Safety Gear: Always wear protective equipment to shield your eyes, hands, and ears from metal shards and loud noise.

Work in a Well-Ventilated Area: Cutting metal can produce fumes and dust. Ensure good ventilation.

Handle with Care: Metal edges can be very sharp. Handle cut pieces with caution to avoid injury.

Keep Workspace Clear: Maintain a clean and organized workspace to prevent accidents.

Additional Considerations

Check Manufacturer’s Guidelines: Some specialty metals may have specific cutting recommendations.

Use Quality Blades: Ensure your cutting tools are equipped with high-quality, sharp blades designed for metal.

Avoid Overheating: Cutting metal can generate heat. Take breaks to prevent overheating, which can affect the metal’s properties.

By following these tips and using the right tools, you can achieve precise and clean cuts on specialty metal roofing, ensuring a professional finish for your project.

Fastening and Maintenance Tips

Choose the Right Fastener:

- Select fasteners that are appropriate for the material you’re working with (wood, metal, plastic, etc.).

- Ensure the size and type (screws, nails, bolts, etc.) match the requirements of the project.

Pre-Drill Holes:

- For hard materials or to prevent splitting in wood, pre-drill holes before inserting screws or nails.

- Use a drill bit slightly smaller than the fastener diameter.

Countersink Screws:

- Use a countersink bit to create a recess for the screw head. This helps to achieve a flush finish and avoid material damage.

Use Washers:

- For bolts and screws, use washers to distribute the load and prevent the fastener from loosening.

Torque Control:

- Avoid overtightening fasteners, which can strip threads or damage the material. Use a torque wrench for precision.

Thread Locking:

- For applications subject to vibration, apply thread-locking adhesive to prevent fasteners from loosening.

Rust Protection:

- For outdoor or high-humidity environments, use galvanized or stainless steel fasteners to prevent rusting.

Correct Driver Bits:

- Use the correct driver bit (Phillips, flathead, Torx, etc.) to prevent stripping the fastener head.

- Maintenance Tips

Regular Inspection:

- Periodically check fasteners for signs of wear, rust, or loosening.

- Tighten or replace fasteners as needed.

Lubrication:

- Apply lubricants to moving parts to reduce friction and prevent wear.

- Use appropriate lubricants for the material and environment (oil, grease, dry lubricants).

Cleanliness:

- Keep fasteners and the surrounding area clean to prevent dirt and debris from causing damage.

- Use a brush or compressed air to clean threaded fasteners before reassembly.

Rust Prevention:

- Apply rust inhibitors or paint to exposed fasteners in corrosive environments.

- Use plastic or rubber caps to protect fasteners from moisture.

Proper Storage:

- Store fasteners in a dry, organized manner to prevent rust and ensure easy access.

- Keep different types and sizes separated to avoid confusion.

Replacement Schedule:

- Establish a regular replacement schedule for fasteners in critical applications.

- Replace fasteners showing signs of wear or damage even if they haven’t failed yet.

Documentation:

- Keep records of maintenance schedules and any issues found with fasteners.

- Document the type and size of fasteners used in different parts of a project for future reference.

Training:

- Ensure personnel are trained in proper fastening techniques and maintenance procedures.

- Stay updated on the latest tools and materials to improve efficiency and effectiveness.

By following these fastening and maintenance tips, you can ensure the longevity and safety of your projects and equipment.

Frequently Asked Questions

What type of blade is used to cut sheet metal with a circular saw?

Use a carbide-tipped blade or a diamond blade specifically designed for cutting metal with a circular saw. Avoid using wood-cutting blades.

Can you cut metal with a regular circular saw?

Yes, you can cut metal with a regular circular saw, but you need to use a carbide-tipped or diamond blade designed specifically for cutting metal. Ensure you follow all safety precautions while cutting.

What blade to cut metal roofing?

To cut metal roofing, use a carbide-tipped or diamond blade designed specifically for metal. Avoid using wood-cutting blades as they can dull quickly and are unsafe.

Conclusion

Cutting metal roofing with a circular saw is doable. You need the right tools and safety gear. Mark your lines and clamp the sheet down tight. Go slow and keep the saw straight for best results. Clean up metal shavings when you finish your cuts.

With practice you will master this useful skill. It saves money on professional installation costs. You can tackle DIY roofing projects with confidence. Safety first and take your time. Soon you will cut metal roofing like a pro.