A corrugated metal roof is made up of metal panels with ridges and grooves. These panels are commonly made from steel, aluminum, or other metals. Corrugated metal roofs are durable, lightweight, and known for their excellent water-shedding properties.

Discover the ins and outs of installing a corrugated metal roof. Our straightforward guide on how to install a corrugated metal roof? ensures a seamless and efficient process, perfect for any DIY enthusiast or homeowner looking to upgrade their property.

Mastering the installation of a corrugated metal roof is essential for a sturdy structure. This guide provides step-by-step instructions, ensuring a seamless process. With attention to detail and the right tools, you can achieve a durable and weather-resistant roof, while also implementing measures to stop thermal expansion noise.

Key Takeaways

- Overlap panels by 1.5 inches for water shedding.

- Use roofing screws with rubber washers.

- Apply sealant to edges to prevent leaks.

- Install ridge caps for added protection.

- Prioritize safety throughout installation.

Corrugated Metal Roofing Advantages

Corrugated metal roofing offers several advantages. Firstly, it’s highly durable, resisting damage from harsh weather conditions like rain, snow, and wind. This durability means fewer repairs and a longer lifespan for your roof. Corrugated metal roofs are lightweight, putting less strain on the structure of your building.

This can be particularly beneficial for older or weaker structures. Moreover, metal roofs are often made from recycled materials, making them an eco-friendly choice. By choosing corrugated metal roofing, you’re not only investing in a sturdy and long-lasting roof but also contributing to environmental sustainability.

Installing The Panels

| Step | Description |

| Position Panels | Align panels along the roof, starting at one end. |

| Secure Panels | Use roofing screws to fasten panels to the roof. |

| Apply Sealant | Apply roofing cement or sealant to edges and overlaps. |

| Install Ridge Caps | Place ridge caps along the peak for added protection. |

| Ensure Safety | Prioritize safety gear and precautions throughout. |

To install the panels, begin by measuring and marking the roof’s surface. Use a tape measure and chalk line to ensure accuracy. Start from the bottom edge and work your way up, marking where each panel will go. Next, cut the panels to the required length using a saw or shears. Ensure they fit the roof dimensions precisely.

Once the panels are cut, it’s time to secure them in place. Align the first panel along the marked line and use roofing screws with rubber washers to fasten it. Repeat this process for each subsequent panel, ensuring proper alignment and overlap. Finally, seal the edges and overlaps with roofing cement to prevent water infiltration.

Corrugated Plastic Roofing

Corrugated plastic roofing is a durable and lightweight option for covering structures. To install it, prepare the roof surface by cleaning it thoroughly. Then, measure and mark the positions for the panels, ensuring proper alignment. Next, cut the panels to size using a saw or shears.

Secure the panels in place using roofing screws with rubber washers, ensuring they overlap properly to prevent leaks. Seal the edges and joints with roofing cement or sealant to enhance water resistance. Finally, inspect the roof for any loose screws or gaps, and clean up any debris from the installation process.

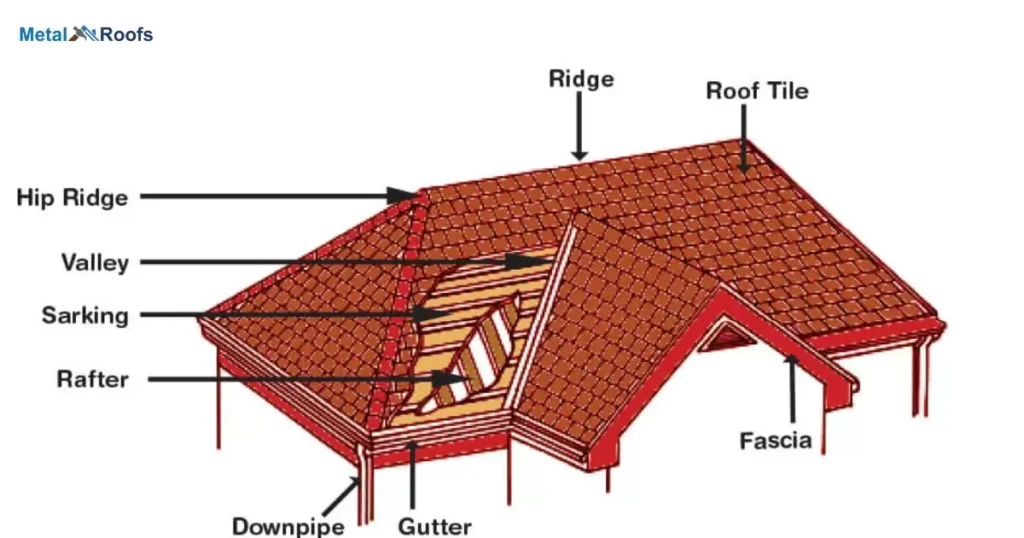

Metal Roof Installation Diagram

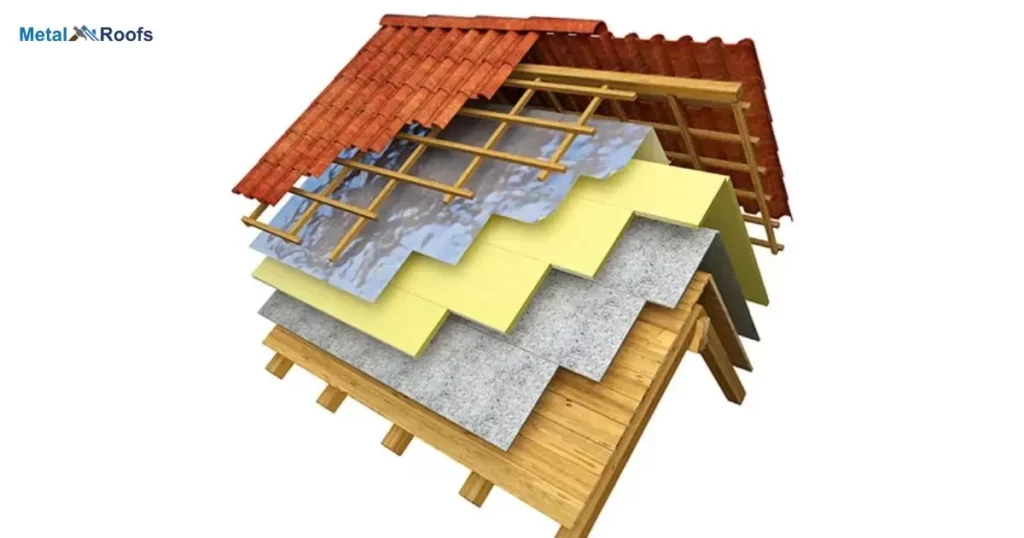

A metal roof installation diagram provides a visual guide for the installation process. It typically includes clear illustrations and labels to help you understand each step. The diagram starts with preparing the roof surface, ensuring it’s clean and flat. Next, it outlines measuring and marking the positions for the metal panels, usually starting from the bottom edge and working upwards.

After that, it shows cutting the panels to fit the roof dimensions accurately using a saw or shears. Once the panels are cut, the diagram demonstrates how to install them sequentially, aligning each panel along the marked positions. It emphasizes using roofing screws with rubber washers to secure the panels in place, ensuring proper overlap and alignment.

Safety Considerations

Safety is paramount when installing a corrugated metal roof. Before starting, ensure the roof is clear and stable. Wear appropriate safety gear like gloves and goggles to protect yourself from potential hazards. Always work carefully and double-check measurements to avoid accidents. If unsure, seek professional help to guarantee a safe installation process.

Safety Precautions For Walking On Metal Roofs

When walking on metal roofs, prioritize safety above all. Wear sturdy footwear with good grip to prevent slipping. Always distribute your weight evenly and avoid stepping on fragile areas. Additionally, be cautious of hot surfaces, especially in sunny weather, and never walk on a metal roof during wet or icy conditions to prevent accidents.

Safety Equipment For Metal Roofing

Safety equipment is crucial for metal roofing projects. Ensure you have gloves and goggles to protect your hands and eyes from sharp edges and debris. Additionally, wear sturdy footwear with good grip to prevent slips and falls, especially on inclined surfaces. Always prioritize safety when working at heights by using a secure harness and ladder.

How To Install A Corrugated Metal Roof Step By Step?

Installing a corrugated metal roof can be a great DIY project if you have the necessary tools and skills. Here’s a step-by-step guide to help you through the process:

Safety Precautions: Before you start, ensure you have all necessary safety equipment like gloves, safety goggles, and a stable ladder. Work with a partner for added safety.

Materials and Tools: Gather all the materials and tools you’ll need for the installation. This typically includes corrugated metal panels, roofing screws, rubber washers, a screw gun or drill with screwdriver bits, a tape measure, chalk line, metal snips, and a saw for cutting panels to size.

Prepare the Roof: Inspect the roof surface to ensure it’s clean, smooth, and free from any debris. Repair any damaged areas and make sure the roof structure is sound.

Measure and Plan: Measure the dimensions of your roof and calculate the number of panels needed. Plan the layout of the panels, ensuring they will overlap correctly and account for any necessary flashing or trim pieces.

Install Underlayment: Depending on your climate and local building codes, you may need to install a waterproof underlayment before laying the metal panels. This helps to prevent leaks and provides added insulation.

Start at the Bottom: Begin installing the panels at the lowest edge of the roof, typically starting from one corner. Align the first panel perpendicular to the roof edge and ensure it overhangs the edge by the desired amount.

Attach Panels: Use roofing screws with rubber washers to secure the panels to the roof structure. Place screws in the crests of the corrugations, driving them through the valleys to prevent leaks.

Overlap Panels: Overlap successive panels according to the manufacturer’s instructions, typically by one or two corrugations. Ensure each panel is aligned straight and level with the previous one.

Cutting Panels: If necessary, use metal snips or a saw to cut panels to size, ensuring a proper fit around roof features such as vents, chimneys, or skylights.

Add Flashing and Trim: Install flashing and trim pieces around roof edges, corners, and any penetrations to provide a finished look and prevent water infiltration.

Seal Joints: Apply silicone sealant to any gaps or joints between panels, flashing, and trim pieces to prevent water leaks.

Finish Up: Once all panels are installed and sealed, inspect the roof for any missed screws or potential leaks. Make any necessary adjustments or repairs.

Clean Up: Remove any leftover materials and debris from the roof and surrounding area.

By following these steps carefully, you can successfully install a corrugated metal roof that provides durable and long-lasting protection for your home. If you’re unsure about any aspect of the installation process, don’t hesitate to consult with a professional roofer for guidance.

Metal Flat Roof

A metal flat roof is a durable option for many buildings. To install it, first, prepare the roof surface by cleaning it thoroughly. Then, measure and mark the positions for the metal panels, ensuring they overlap properly. Next, cut the panels to fit the dimensions of the roof using a saw.

After that, secure the panels in place with roofing screws every few inches along the edges. Apply roofing sealant to the edges and overlaps to prevent leaks. Finally, inspect the roof for any loose screws or gaps, and clean up any debris. With proper installation, a metal flat roof can provide long-lasting protection for your building.

Corrugated Metal On Wall

Corrugated metal on a wall adds an industrial touch. To start, prepare the wall surface, ensuring it’s clean and smooth. Next, measure and mark the positions for the metal panels on the wall. Then, cut the panels to size using shears or a circular saw.

Install the panels, securing them with screws along the edges and ridges. Finally, inspect the wall for any gaps or loose screws, and make necessary adjustments. With these steps, you can easily install corrugated metal on your wall, enhancing its appearance with a modern flair.

Additional Tips And Considerations

When installing a corrugated metal roof, consider the climate and weather conditions of your area for optimal performance. Ensure proper ventilation to prevent moisture buildup and prolong the life of your roof. If unsure, consult with a roofing professional for guidance and advice tailored to your specific needs and circumstances.

Weather Conditions

Consider weather conditions before installing a corrugated metal roof. Avoid installation during rainy or windy weather to ensure safety and proper adhesion. If possible, choose a dry and calm day for the installation to facilitate the process and minimize potential complications.

Safety Precautions

When it comes to safety precautions, remember to secure ladders properly before climbing onto the roof. Avoid working on the roof during adverse weather conditions like rain or strong winds. Keep children and pets away from the work area to prevent accidents. Always prioritize safety above all else to ensure a successful and incident-free installation process.

Maintenance And Repair

When it comes to maintenance and repair of a corrugated metal roof, regular inspections are key. Check for loose screws or damaged panels and replace them promptly. Keep gutters clean to prevent water buildup, which can lead to corrosion. Apply a fresh coat of sealant as needed to maintain the roof’s integrity and prolong its lifespan.

How To Install Corrugated Metal Roofing On A Shed?

To install corrugated metal roofing on a shed, begin by preparing the roof surface. Clean it thoroughly and ensure it’s flat. Then, measure and mark where each panel will go using a chalk line. Cut the panels to size if needed using shears or a circular saw. Next, start at one end and align the first panel along the marked line.

Secure it with roofing screws, placing them every 12 inches along the ridges. Repeat this process for each subsequent panel, overlapping them to prevent leaks. Once all panels are in place, apply roofing sealant along the edges and overlaps to ensure waterproofing. Finally, inspect the roof for any loose screws or gaps, and clean up any debris.

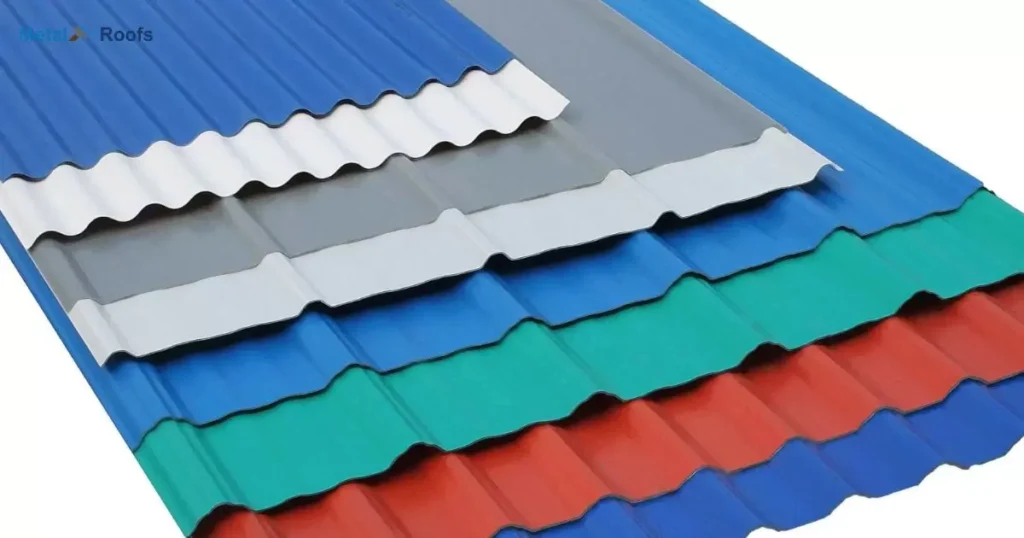

Types Of Corrugated Metal Roofing

Corrugated metal roofing comes in various types, each with its own unique characteristics suited for different applications. Here are some common types:

Galvanized Steel: This is one of the most popular types of corrugated metal roofing. It’s coated with a layer of zinc to prevent corrosion, making it durable and long-lasting.

Galvalume Steel: Similar to galvanized steel, but with a combination of zinc and aluminum coating. Galvalume offers enhanced corrosion resistance and is often preferred in coastal or high-moisture environments.

Aluminum: Corrugated roofing made from aluminum is lightweight, corrosion-resistant, and suitable for coastal areas or regions with high humidity.

Copper: While less common due to its cost, copper corrugated roofing offers unmatched durability, aesthetic appeal, and resistance to corrosion. Over time, it develops a unique patina that adds character to the building.

Stainless Steel: Known for its exceptional strength, durability, and resistance to corrosion, stainless steel corrugated roofing is commonly used in industrial and commercial settings.

Corrugated Fiberglass: Fiberglass corrugated roofing is lightweight, translucent, and provides natural lighting to the space beneath. It’s commonly used in agricultural and industrial buildings.

Polycarbonate: Similar to fiberglass, polycarbonate corrugated roofing is lightweight and translucent. It offers high impact resistance and UV protection, making it suitable for greenhouse applications or areas requiring natural light.

PVC (Polyvinyl Chloride): PVC corrugated roofing is lightweight, durable, and cost-effective. It’s commonly used in agricultural and DIY projects due to its ease of installation.

choosing the type of corrugated metal roofing, factors such as climate, budget, aesthetic preferences, and intended use should be considered to ensure the best fit for your project.

Frequently Asked Questions

What Do You Put Under Corrugated Metal Roofing?

Under corrugated metal roofing, you typically put roofing felt or synthetic underlayment.

How Do You Attach Corrugated Roofing?

To attach corrugated roofing, prepare, measure, secure with screws, trim if necessary, seal edges, inspect, and clean up.

How Far To Overlap Corrugated Metal Roofing?

Overlap corrugated metal roofing by at least 1.5 inches for effective water shedding and leak prevention.

Conclusion

Installing a corrugated metal roof requires careful planning and execution. By following proper measurements and overlap guidelines, you can ensure a durable and weather-resistant roofing system. To prioritize safety and attention to detail throughout the installation process.

With the right tools and techniques, you can successfully complete a corrugated metal roof installation. Regular maintenance and inspections will help prolong the lifespan of your roof, providing long-term protection for your property.