Metal roof screw placement is about putting screws in the right spots to keep the roof strong and waterproof. It stops leaks and makes sure the roof stays put during storms. Put screws where the panels meet and around the edges for the best results.

When it comes to keeping your metal roof secure, proper screw placement is key. Secure those screws in the right spots, and you’ve got a roof that can weather any storm. Metal roof screw placement ensures your roof stays strong and leak-free for years to come.

Metal roof screw placement is crucial for ensuring the durability and resilience of your roof. You’re on the right track when you consider how far apart should screws be on a metal roof.

It’s the backbone of a sturdy, reliable roof. Properly positioning those screws ensures your roof can withstand any weather condition without worry.

Key Takeaways

- Metal roof screw placement is vital for stability and weatherproofing.

- Proper placement prevents leaks and secures against wind uplift.

- Strategic positioning along seams and edges enhances longevity.

Types of Metal Roof Screws

Metal roof screws come in various types and designs, each suited for specific applications and conditions. Here are some common types:

Woodgrip Screws

| Woodgrip Screws | Description |

| Type | Self-tapping screws designed for wood-to-metal |

| Features | Sharp point, coarse threads, hex washer head |

| Application | Ideal for attaching metal roofing to wooden structures |

| Benefits | Strong grip, easy installation, resistant to corrosion |

Woodgrip screws are a common type of metal roof screw. They have coarse threads for secure attachment to wood substrates. These screws are designed specifically for metal roofing applications.

Self-Drilling Screws

Types of metal roof screws include self-drilling screws. These screws have a drill bit tip, eliminating the need for pre-drilling. They streamline installation and provide a secure attachment for metal roofing panels.

Stitch Screws

In the realm of metal roof screws, stitch screws play a crucial role. These specialized screws are shorter and designed to stitch metal panels together, ensuring a tight fit. They provide added support and stability to the roof structure.

Lap-Tek Screw System

Under the category of types of metal roof screws the Lap-Tek screw system stands out. It’s designed for secure fastening of metal roofing panels without pre-drilling. This system ensures efficient installation and reliable performance.

Pancake Head Screw System

Types of metal roof screws include the Pancake Head Screw System. These screws feature a flat head design for a sleek appearance. They provide secure fastening while maintaining a low-profile finish.

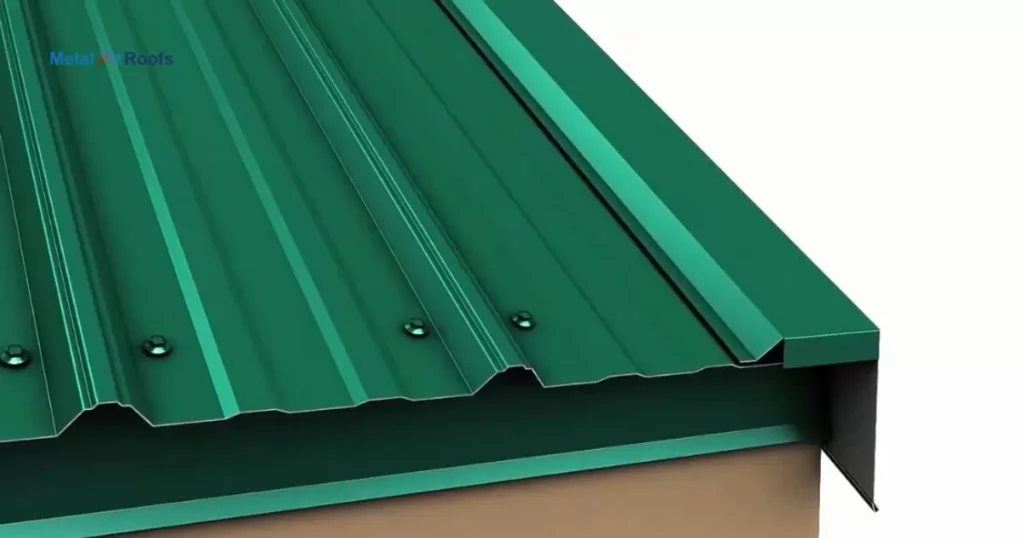

Proper Screw Placement

Proper screw placement is essential for a secure metal roof. Ensure screws are positioned correctly along seams and edges. This prevents leaks and strengthens the roof against wind. Secure placement guarantees long-lasting protection.

Strategic screw placement enhances the roof’s performance. Securing screws at designated intervals, stability is ensured. This means your metal roof can withstand various weather conditions with confidence.

Screw Spacing

When it comes to metal roof screw placement, spacing matters. The distance between screws determines the strength and integrity of the roof. Too far apart, and the panels may not hold up against strong winds or heavy loads.

Proper spacing ensures even distribution of weight and enhances the roof’s durability. Typically, screws should be spaced evenly along the seams and edges of the metal panels. This spacing provides adequate support and helps maintain the structural integrity of the roof.

Screw Alignment

When it comes to metal roof screw placement, screw alignment is essential. Ensuring screws are straight and aligned correctly along the seams and edges of the metal panels is crucial. Proper alignment prevents leaks and maintains the structural integrity of the roof.

If screws are misaligned, they may not properly secure the panels, leading to potential issues down the line. Leaks and weak spots can develop, compromising the overall effectiveness of the roof.

Sealant Tape or Caulk

Sealant tape or caulk is essential for ensuring the tightness of metal roof screw placements. It provides an extra layer of protection against water penetration and helps to seal any gaps or openings.

Sealant tape is often preferred for its ease of application and durability, while caulk can be used for more intricate or hard-to-reach areas. Both sealant tape and caulk play a vital role in enhancing the weatherproofing of metal roofs.

They act as barriers against moisture, preventing potential leaks and water damage. Using sealant tape or caulk, proper application is key to maximizing their effectiveness and maintaining the integrity of the roof structure over time.

Screw Location Recommendations

When it comes to screw location recommendations for metal roofs, focus on the seams and edges. Placing screws along these areas ensures maximum stability and weather resistance. Aim for uniform spacing to distribute the load evenly across the roof.

Consider the manufacturer’s guidelines for specific recommendations tailored to your roof’s design and material. Proper screw placement is key to a durable and long-lasting metal roof.

Screw Installation Techniques

When it comes to screw installation techniques, precision is key. Ensuring screws are driven straight and at the correct depth is crucial for a strong hold. Using a drill with the right bit size can help avoid stripping or damaging the screw heads.

Applying consistent pressure while driving screws can prevent them from becoming loose over time. It’s important to follow manufacturer guidelines for the specific type of screw being used. Taking care during installation ensures a secure and reliable fastening for various construction projects.

Screw Placement for Different Metal Roofing Panels

The placement of screws for different metal roofing panels depends on several factors, including the type of panel profile, the manufacturer’s recommendations, and local building codes. Here’s a general guideline:

Panel Profile: Different metal roofing panels have different profiles, such as standing seam, corrugated, or ribbed. The screw placement will vary based on the design of the panel.

Manufacturer’s Recommendations: Always refer to the manufacturer’s installation instructions for the specific roofing panels you’re using.

Local Building Codes: Local building codes may also dictate certain requirements for metal roofing installation, including screw spacing and attachment methods.

For standing seam panels: Typically, screws are placed in the flat areas between the raised seams. The exact spacing will vary depending on factors such as wind load requirements and panel dimensions.

For corrugated or ribbed panels: Screws are usually placed through the top of the ridges. Again, spacing will vary based on the manufacturer’s recommendations and local building codes.

Pre-drilling: In some cases, pre-drilling may be necessary to prevent the panels from cracking or deforming during installation, especially with harder materials like steel.

Sealants and Washers: Using appropriate sealants and rubber washers with screws can help prevent leaks and ensure a watertight seal.

Consultation: If you’re unsure about the proper screw placement for your specific metal roofing panels, consider consulting with a professional roofer or contractor who has experience with metal roofing installations.

Proper installation is crucial for the performance and longevity of a metal roof, so it’s essential to follow the manufacturer’s recommendations and local building codes carefully.

Screw Fastening in Corrugated Metal Paneling

When it comes to screw fastening in corrugated metal paneling, precision is key. Ensure screws are placed evenly along the ridges to maintain structural integrity. This method helps distribute weight evenly and prevents panels from warping or bending.

Using the correct type and size of screws is essential for secure fastening. Opt for self-drilling screws designed specifically for metal paneling. These screws penetrate the metal easily without the need for pre-drilling, making installation quicker and more efficient.

Roofing Installation Tips

Installing a roof properly is crucial for protecting a building from the elements and ensuring its longevity. Here are some tips for roofing installation:

Safety First: Prioritize safety by using proper safety equipment such as harnesses, helmets, and non-slip footwear. Ensure the work area is clear of debris and hazards.

Choose the Right Materials: Select high-quality roofing materials suitable for the climate and architecture of the building. Consider factors such as durability, energy efficiency, and aesthetic appeal.

Prepare the Roof Surface: Ensure the roof deck is clean, dry, and free from any debris or protrusions. Repair any damaged or rotted sections before starting the installation.

Proper Ventilation: Install adequate ventilation to prevent moisture buildup, which can lead to mold, rot, and premature roof deterioration. Ventilation also helps regulate temperature and energy efficiency.

Follow Manufacturer Guidelines: Adhere to the manufacturer’s instructions and guidelines for installing roofing materials. This ensures proper installation and maintains warranty coverage.

Use the Right Tools: Use appropriate tools and equipment for the job to ensure efficiency and accuracy. Common roofing tools include nail guns, roofing hammers, utility knives, and chalk lines.

Proper Installation Techniques: Pay attention to the correct installation techniques for the specific roofing materials being used, it’s asphalt shingles, metal roofing, tiles, or other types.

Pay Attention to Flashing and Sealing: Properly install flashing around roof penetrations such as chimneys, vents, and skylights to prevent water infiltration.

Secure Roofing Materials: Ensure roofing materials are securely fastened to the roof deck to withstand wind uplift and other environmental stresses.

Inspect and Maintain: Regularly inspect the roof for signs of damage or wear, and promptly address any issues to prevent further damage.

Consider Professional Help: For complex roofing projects or if you lack experience, consider hiring a professional roofing contractor.

Frequently Asked Questions

What is the spacing for screws on a metal roof?

Spacing for screws on a metal roof is typically every 12 to 24 inches along seams and edges for stability and durability.

What is the spacing for metal roof strapping?

Metal roof strapping spacing is usually 24 inches apart for optimal support and structural integrity.

How far apart should screws be for a standing seam metal roof?

For a standing seam metal roof, screws are usually spaced 12 to 24 inches apart along the seams to ensure stability.

Conclusion

Metal roof screw placement is vital for a durable roof. Strategic placement prevents leaks and ensures stability during storms. Proper positioning along seams and edges is crucial. Investing time in screw placement now saves hassle later.

Mastering metal roof screw placement is key. It’s the foundation of a reliable, long-lasting roof. Take care to position screws correctly for optimal performance and peace of mind.