Metal roof sound insulation reduces noise from rain and other sources. It involves adding materials like underlayment and insulation. Acoustic panels and mass-loaded vinyl help absorb and block sound effectively. Proper sealing and consulting a professional are crucial for best results.

Metal roof sound insulation solves it. Blocks unwanted outdoor sounds. Enjoy serene indoor ambiance. Simple, effective solutions exist. Embrace blissful silence at home. Discover metal roof sound insulation. Reclaim your peace and quiet.

Metal roofs amplify exterior noise. Sounds reverberate inside homes. Insulation provides a solution. Blocks unwanted noise transmission. Creates a peaceful living space. Various insulation options exist. Rigid foam boards work well. Spray foam is also effective.

Key Takeaways

- Metal roofs can be noisy during rain or hail.

- Insulation with materials like fiberglass or foam can reduce sound transmission.

- Underlayment and roof design play key roles in noise reduction.

- Ceiling treatments and coatings can further dampen sound.

- Consult professionals for customized solutions.

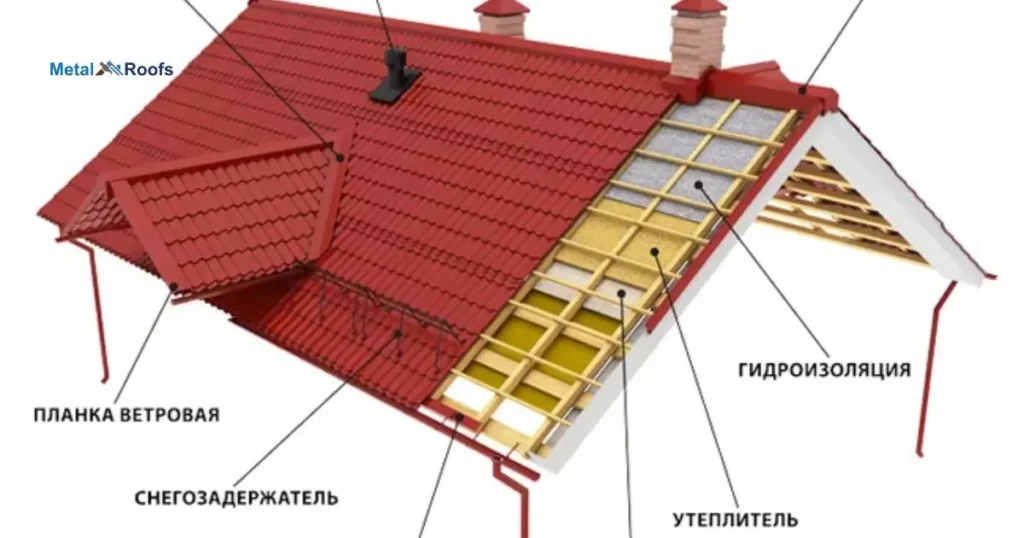

Metal Roofing Systems Design Guide

Metal roofing systems require careful design considerations. Insulation materials like fiberglass or foam are crucial for reducing noise, especially during rain or hailstorms. Underlayment and roof design play significant roles in minimizing sound transmission.

Metal roof thermal expansion noise can be effectively minimized by incorporating acoustic tiles or panels in the ceiling. Consulting professionals for customized solutions is advisable to ensure optimal performance and comfort.

Metal Roof System Underlayments

| Underlayment Material | Features |

| Synthetic Underlayment | Lightweight, resistant to tearing, UV resistant, waterproof |

| Felt Underlayment | Traditional option, affordable, water-resistant, good for temporary use |

| Rubberized Underlayment | Excellent for noise reduction, waterproof, durable |

| Foam Underlayment | Provides insulation and soundproofing, lightweight, easy to install |

Metal roofs sometimes produce noise, especially during rain or hailstorms. To reduce this noise, consider using underlayments beneath the metal roof. Underlayments can be made of rubberized or foam-based materials and help dampen sound vibrations.

They provide an additional layer of insulation between the metal roof and the interior of the building. This extra barrier can significantly minimize the transmission of noise into the living or working spaces below, enhancing comfort and tranquility.

Fastener Pullout Resistances for Insulation Attachment

When attaching insulation, fastener pullout resistance is crucial. It ensures the insulation stays in place, enhancing effectiveness. Using sturdy fasteners like screws or nails is essential. They provide a secure hold against external forces.

Insufficient pullout resistance can lead to insulation displacement. This can compromise energy efficiency and structural integrity. Therefore, proper selection of fasteners and installation techniques is paramount.

Firestone Fastener Types

Firestone fasteners are used in various applications, particularly in roofing systems manufactured by Firestone Building Products. Here are some common types of fasteners used in Firestone roofing systems:

Mechanical Fasteners: These are typically screws or nails used to secure roofing membranes to the substrate. They often feature a self-drilling or self-tapping design for ease of installation.

Plates and Screws: Plates are often used in conjunction with screws to secure roofing membranes. The plates help distribute the load over a larger area, reducing stress on the membrane.

Pressure Plates: These are used in conjunction with screws to secure insulation boards or other materials to the substrate. They help provide a secure attachment while also preventing over-compression of the insulation.

Batten Strips: These are strips of material, often made of metal or plastic, used to secure roofing membranes in place. They are typically installed over the membrane and fastened to the substrate.

Adhesive Fasteners: In some cases, adhesives are used instead of mechanical fasteners to bond roofing materials to the substrate. These adhesives are specially formulated to provide a strong, durable bond that withstands environmental conditions.

Barbed Plates: These are similar to regular plates but feature barbs or ridges that help hold the membrane in place more securely.

Ballasted Fasteners: In ballasted roofing systems, fasteners may be used to secure various components such as insulation or cover boards to the substrate before ballast materials such as gravel or pavers are added.

Tube Fasteners: These are cylindrical fasteners that are often used in conjunction with plates to secure roofing membranes. They are typically installed using a tube applicator.

These are just a few examples of fasteners used in Firestone roofing systems. The specific type of fastener and installation method will depend on the requirements of the project and the specific roofing system being used.

Structural Deck Classification

Structural deck classification categorizes decks based on their materials and design. The classification helps engineers choose the right deck for construction projects. Decks are typically classified as composite, non-composite, or form decks, each with distinct characteristics and applications.

Composite decks combine steel and concrete for added strength and durability, making them suitable for heavy-duty structures. Non-composite decks, on the other hand, are made solely of steel and are often used in lighter applications where cost-effectiveness is key.

Consultation and Substrate Requirements

When it comes to consultation and substrate requirements for metal roof sound insulation, it’s essential to seek expert advice. Consulting with a professional roofing contractor or acoustic engineer can provide valuable insights tailored to your specific situation.

They can assess your needs and recommend the most effective solutions to minimize noise transmission and improve interior comfort. Substrate requirements is crucial for successful sound insulation. Proper substrate preparation ensures that insulation materials adhere securely and perform optimally.

Thermal Movement of Metal Roof Panels

Metal roof panels expand and contract due to changes in temperature. This movement, known as thermal expansion, can cause issues if not properly managed. Without proper allowance for thermal movement, metal roof panels may buckle or warp over time.

To address thermal movement, installers use techniques such as leaving gaps between panels and incorporating expansion joints. These measures allow the panels to expand and contract without causing damage.

Soundproofing Methods for Metal Roofs

When dealing with noisy metal roofs, consider insulation with materials like fiberglass or foam. Opt for quality underlayment and standing seam roofs to reduce noise transmission. Enhance soundproofing with acoustic tiles or coatings.

Insulating the Attic

To complement soundproofing methods for metal roofs, insulating the attic is crucial. Use fiberglass or cellulose insulation to dampen noise and regulate temperature. Seal any gaps or cracks to prevent air leaks, further enhancing insulation effectiveness.

Insulating the Walls

To complement soundproofing methods for metal roofs, insulating the walls is crucial. Use materials like fiberglass or foam to dampen sound transmission. Ensure proper installation to maximize effectiveness. Professional advice can help tailor solutions to specific needs.

Covering or Insulating the Ceiling

To further reduce noise from metal roofs, consider covering or insulating the ceiling. Acoustic tiles or panels can absorb sound effectively. Professional guidance ensures the right approach for optimal soundproofing.

Use of Quiet Batt Soundproofing Insulation

When seeking soundproofing for metal roofs, consider using Quiet Batt insulation. This specialized material effectively absorbs sound vibrations. Install it between the metal roof and the building’s interior for optimal noise reduction.

Decorative Acoustic Panels for Sound Absorption

To further enhance soundproofing for metal roofs, consider incorporating decorative acoustic panels for sound absorption. These panels not only reduce noise but also add aesthetic appeal to the interior space.

Metal Roof Noise Reduction and Soundproofing

Metal roofs sometimes make a lot of noise when it rains or hails. To reduce this noise, insulation materials like fiberglass or foam can be placed between the roof and the interior. Quality underlayment and roof design also play important roles in minimizing sound transmission.

Adding acoustic tiles or panels to the ceiling and applying sound-dampening coatings to the metal roof can further reduce noise levels. Consulting with professionals can help find the best solution tailored to specific needs.

Frequently Asked Questions

Can You Soundproof A Metal Roof?

Yes, you can soundproof a metal roof by adding insulation materials, using quality underlayment, and opting for standing seam roofs.

How Do You Deaden The Sound Of A Metal Roof?

To muffle the noise of a metal roof, insulate with materials like fiberglass or foam, use quality underlayment, and consider acoustic tiles or panels.

What Is The Best Roof Material For Noise Reduction?

Concrete, clay tiles, slate, or rubber are superior for noise reduction in roofing compared to metal or asphalt shingles.

Conclusion

Insulating metal roofs is a wise choice. It eliminates unwanted noise from outside sources. Enjoy peaceful living spaces within your home. Consult professionals for proper installation and guidance.

Invest in quality insulation for lasting results. Rigid foam boards or spray foam work best. Embrace the serenity of a quiet environment. Experience the transformative power of sound insulation.