Metal roofs are durable coverings. They repel weather and fire risks. Materials include steel and aluminum. Long lifespan makes them cost-saving. Styles mimic slate, shingles, tiles. Benefits include low maintenance. Recycled options are eco-friendly. Proper installation is crucial.

Metal roofs need proper slope pitch. Too flat risks water accumulation. what is the minimum pitch on a metal roof? Experts recommend four-inch minimum. Codes vary by region and climate. Proper pitch ensures roof longevity. Ignoring pitch leads to problems.

Metal roofs need the right pitch to prevent water pooling and leaks. Climate affects pitch needs; snowy areas need steeper slopes, while tropical regions can have lower pitches. To walk on a metal roof without denting it, ensure the pitch is suitable for your roof type.

Key Takeaways

- Raised seams prevent water intrusion.

- Wavy patterns require a steeper pitch to avoid pooling.

- Follow specific manufacturer recommendations.

- Ensure roof pitch meets local regulations.

- Steeper pitch may be needed in areas with heavy rainfall or snowfall.

Minimum Slope For Metal Roof

The minimum slope for a metal roof depends on the type. For standing seam metal roofs, the minimum slope is 1:12. This means the roof rises 1 inch for every 12 inches. Standing seams help keep water out. They work well even with a low slope.

For corrugated metal panels, the minimum slope is 3:12. This means the roof rises 3 inches for every 12 inches. The wavy pattern needs a steeper slope. It helps water flow off quickly. Always check the manufacturer’s guidelines. Also, local building codes matter too.

Minimum Slope On Metal Roof

| Metal Roof Type | Minimum Slope Required |

| Standing Seam | 1/4:12 (2%) |

| Corrugated Metal | 1/4:12 (2%) |

| Ribbed Metal Panels | 1/4:12 (2%) |

| Snap-lock Panels | 3:12 (25%) |

| Mechanically Seamed | 1:12 (8.33%) |

The minimum slope for a metal roof depends on the type. Standing seam roofs need at least a 1:12 pitch. This means the roof should rise one inch for every 12 inches it runs. This low pitch helps water run off easily. It also prevents leaks and pooling.

Corrugated metal panels need a steeper slope. The minimum pitch is 3:12. This helps channel water effectively. It prevents water from collecting and causing leaks. Always check manufacturer guidelines and local codes. In areas with heavy rain or snow, consider a steeper pitch for safety.

Minimum Pitch On Metal Roof

The minimum pitch on a metal roof varies by type. For standing seam roofs, the pitch should be at least 1:12. These roofs have raised seams that prevent water from leaking. Corrugated metal panels, on the other hand, require a steeper pitch of 3:12. This is because their wavy patterns need more slope to avoid water pooling.

Always follow manufacturer guidelines for precise pitch requirements. Also, ensure compliance with local building codes. In areas with heavy rainfall or snow, a steeper pitch might be necessary for proper water runoff.

Lowest Pitch For Metal Roof

Metal roofs come in different styles, each with its own pitch requirement. Standing seam roofs need a minimum pitch of 1:12 to keep water out. These roofs feature raised seams that help in preventing leaks. On the other hand, corrugated metal panels require a steeper pitch of 3:12.

Their wavy patterns channel water effectively, but a steeper slope is necessary to prevent pooling and leaks. Following the manufacturer’s guidelines ensures proper installation and performance. Local building codes also dictate the minimum pitch required.

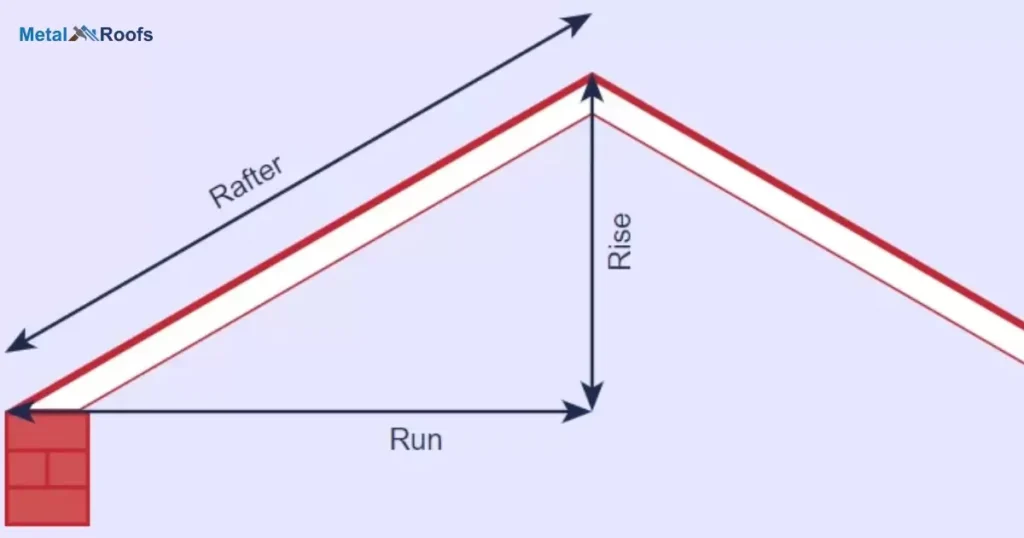

Metal Roof Pitch Calculator

Need to calculate the pitch of your metal roof? Use a metal roof pitch calculator. It’s simple and efficient. Input the required parameters – like roof length and rise – and get the pitch instantly. These calculators are widely available online and are user-friendly.

Just plug in the numbers, hit ‘calculate’, and you’re done. It’s a handy tool for homeowners and contractors alike. With accurate pitch measurements, you can ensure proper installation and effective water runoff.

What Is A 3/12 Roof Pitch?

A 3/12 roof pitch means the roof rises 3 inches vertically for every 12 inches it runs horizontally. It’s a low slope, not too steep, not too flat. This pitch is common in residential construction for its balance of aesthetics and functionality. It allows for efficient water runoff without being too difficult to walk on for maintenance.

A 3/12 pitch suits various roofing materials, including asphalt shingles, metal panels, and tiles. It’s versatile, suitable for regions with moderate weather conditions. A 3/12 pitch provides enough slope to prevent water from pooling while still offering an accessible surface for installation and upkeep.

What Are The Benefits Of A Shallower Pitch?

A shallower pitch refers to a roof with a lower slope angle. Here are some benefits of shallower pitches:

Cost-Effectiveness: Shallower pitches typically require less material and labor to construct compared to steeper pitches, making them more cost-effective.

Ease of Maintenance: It’s generally easier to access and maintain a roof with a shallower pitch. This can reduce maintenance costs over time.

Aesthetic Appeal: Shallower pitches can provide a more modern and sleek aesthetic to a building, especially in contemporary architecture where low-slope roofs are common.

Space Utilization: Shallower pitches can allow for more usable space in attics or upper floors of a building since there’s less space taken up by the roof structure itself.

Reduced Snow Buildup: In regions where snowfall is common, shallower pitches can help prevent excessive snow buildup, reducing the risk of roof damage or collapse.

Ease of Installation: Shallower pitches are often easier and quicker to install, which can help shorten construction time and minimize labor costs.

Energy Efficiency: While not as effective as steeper pitches for natural ventilation and cooling, shallower pitches can still provide some passive cooling benefits, particularly when combined with appropriate insulation and ventilation systems.

It’s important to note that the suitability of a shallower pitch depends on various factors such as climate, building design, and local building codes. In regions with heavy rainfall or high winds, for example, steeper pitches may be necessary to ensure proper water drainage and wind resistance.

Minimum Pitch For Metal Roof Tiles

Metal roof tiles have specific pitch requirements to ensure proper water runoff. For standing seam tiles, a minimum pitch of 1:12 is recommended. These tiles feature raised seams that help prevent water from seeping through.

Corrugated metal tiles, on the other hand, require a steeper pitch of 3:12. Their wavy patterns necessitate better drainage to avoid water pooling. Always adhere to manufacturer guidelines for accurate pitch specifications. It’s crucial to comply with local building codes regarding roof pitch.

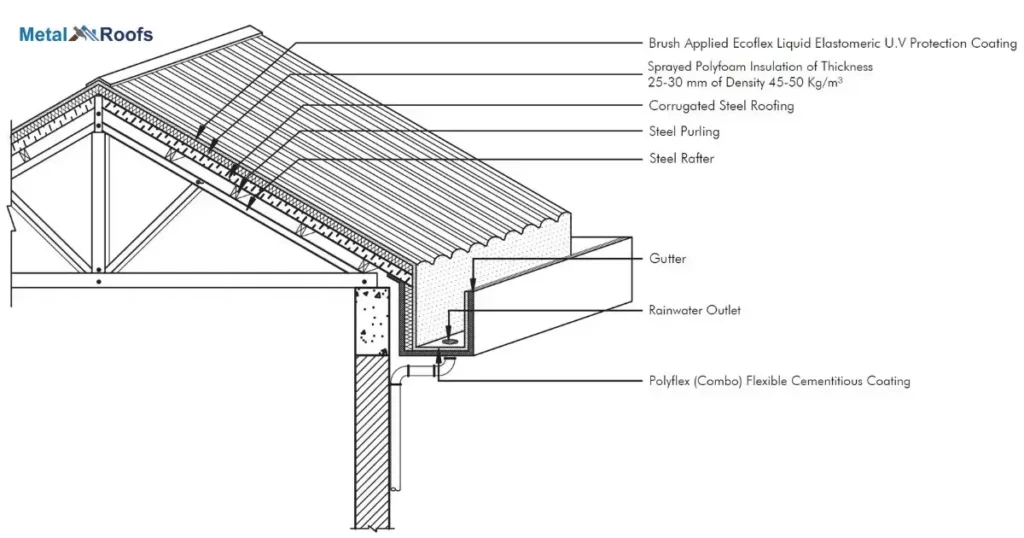

What Is The Minimum Pitch For Metal Roof Insulation?

When insulating a metal roof, the minimum pitch matters. For standing seam roofs, a pitch of 1:12 is advisable, as their raised seams aid in water runoff. Corrugated metal panels, Require a steeper pitch of 3:12 to prevent water pooling.

What Is The Typical Insulation Type?

Under what is the minimum pitch for metal roof insulation?, common types include fiberglass, foam board, and spray foam. They vary in thermal resistance and moisture control, critical for energy efficiency.

How Does It Impact Energy Efficiency?

The minimum pitch for metal roof insulation affects energy efficiency significantly. A proper pitch ensures efficient runoff, reducing water accumulation and potential energy loss. It also helps maintain insulation integrity, optimizing temperature regulation inside buildings.

What Are The Installation Considerations?

When installing metal roof insulation, consider factors like the roof’s pitch. Proper installation ensures effective insulation and prevents heat loss. Adhering to manufacturer guidelines and local building codes is essential for a successful installation.

Frequently Asked Questions

What Is The Best Pitch For A Metal Roof?

For optimal performance, consider a 1:12 pitch for standing seam roofs and at least 3:12 for corrugated metal panels, adhering to manufacturer guidelines and local codes.

What Is The Minimum Roof Pitch?

The minimum roof pitch varies for different materials for standing seam metal roofs, it’s 1:12, and for corrugated metal panels, it’s 3:12, with both designed to prevent water pooling.

What Is The Minimum Pitch For Metal Roof Tiles?

Metal roof tiles typically require a minimum pitch of 3:12 for effective water runoff, preventing leaks and damage.

Conclusion

The minimum pitch requirements for metal roofs is crucial. Following manufacturer guidelines and local codes ensures proper installation. Adequate pitch prevents water pooling, safeguarding against potential leaks and damage. Considering the climate can help determine the optimal pitch for effective drainage.

Ultimately, maintaining the correct pitch promotes the longevity of metal roofs. It ensures they perform optimally, providing reliable protection for buildings. By adhering to these guidelines, property owners can enjoy durable and weather-resistant roofing solutions.