A caulk gun can become difficult to squeeze and dispense caulk properly when the caulk tube is low and air gets in, the caulk is expired, there is a clog or dried caulk in the tip, or the caulk gun needs lubrication to function smoothly again, allowing the trigger to move easily.

Using a caulk gun should be easy, so why is a caulk gun hard to squeeze? From dried caulk clogging the tip to needing lubricant inside, there are a few reasons that make dispensing caulk difficult despite squeezing the trigger hard, leaving you to wonder why it feels impossible to use.

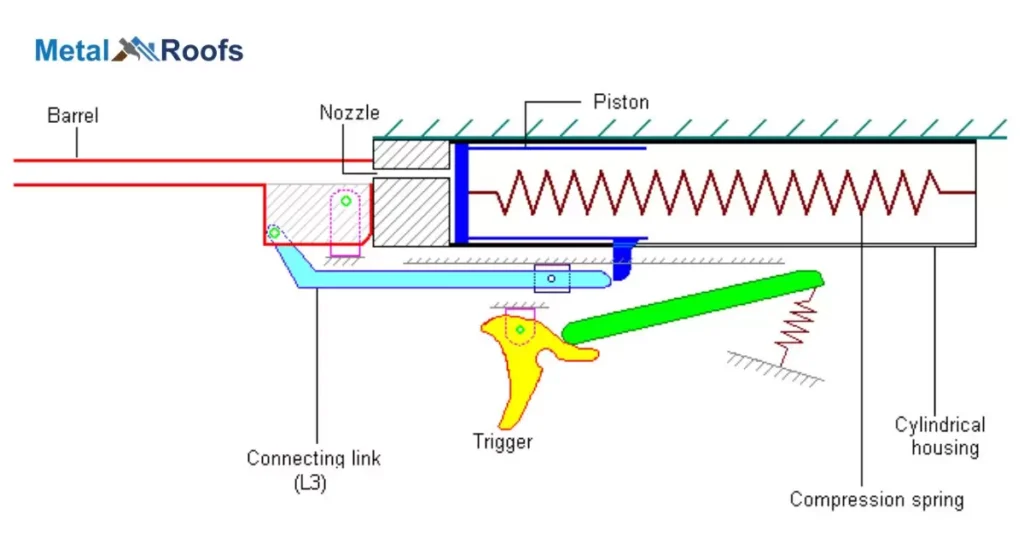

A caulk gun works by using leverage from the trigger to push caulk out. So issues like dried caulk, air bubbles, expired tubes, or a lack of lubrication inside can prevent the caulk from moving smoothly. This makes the trigger very difficult to squeeze.

Key Takeaways

- Causes of difficulty: dried caulk, mechanical problems

- Regular maintenance ensures smooth operation

- Proper technique enhances efficiency

- Consider alternative caulk gun types for easier use

- Seek professional assistance for persistent issues

Metal Roofing Challenges

Metal roofing poses unique challenges during installation. The precise measurements required can make it tricky to fit the metal sheets properly. Fluctuations in temperature can cause the metal to expand and contract, potentially leading to issues like buckling or warping.

Metal roofs can be noisy during rain or hailstorms, with some homeowners reporting that Metal Roofs Make Popping Noises. This can be bothersome for homeowners, although proper insulation can help reduce the noise. Despite these challenges, metal roofing remains popular for its durability and modern appearance.

Proper Loading and Application Techniques

- Load the caulk cartridge straight into the gun to prevent jams.

- Press firmly to secure the cartridge in place.

- Cut the cartridge tip at a slight angle to control the flow of caulk and reduce resistance.

- Hold the gun at a 45-degree angle to the surface for optimal control during application.

- Squeeze the trigger steadily and evenly, avoiding sudden jerks.

- Smooth the caulk with a damp finger or tool immediately after application for a clean finish.

Correct Nozzle Angle for Even Flow

One reason caulk guns might be hard to squeeze is due to incorrect nozzle angle. Ensure the nozzle is cut at a 45-degree angle for even flow. Holding the gun at this angle allows for smoother dispensing of caulk without excess force.

When the nozzle is angled correctly, it reduces resistance in the caulk tube. This makes it easier to control the flow and prevents uneven application. Correcting the angle can significantly improve the ease of use and effectiveness of the caulk gun.

Gravity Assistance for Caulk Flow

In some cases, caulk guns might be hard to squeeze due to gravity assistance issues. When the caulk tube is near empty, gravity makes it harder for the plunger to push the remaining caulk out. Additionally, air bubbles can form in the caulk, creating resistance against the plunger.

To address this, try tipping the caulk gun slightly upward to allow gravity to assist the flow of caulk. This can help reduce the effort needed to squeeze the trigger and ensure a smoother application. Gently tapping the sides of the caulk tube can help dislodge any trapped air bubbles, further easing the flow of caulk.

Trigger Pressure for Controlled Application

When considering why a caulk gun might be hard to squeeze, trigger pressure for controlled application is a crucial factor. The pressure needed to squeeze the trigger depends on the viscosity of the caulk being used. If the caulk is thick, more pressure is required, making it harder to control the flow.

The design of the caulk gun’s trigger mechanism can affect how much pressure is needed to dispense the caulk evenly. Adjusting the trigger pressure and finding the right balance can help achieve a controlled application without straining your hand.

Metal Roofing Surface Preparation

- Clean the roof surface thoroughly, removing all debris, dirt, and existing roofing materials.

- Inspect the roof for damage, leaks, or structural issues that need repair before installation.

- Address any dents, leaks, or imperfections to ensure a smooth and even surface for the metal panels.

- Apply a primer or rust-inhibiting coating to protect the metal and enhance its durability.

- Proper surface preparation is essential for optimal performance and longevity of the metal roofing system.

Types of Caulk Guns

Caulk guns come in manual, pneumatic, and battery-powered types. Manual guns require hand pressure, while pneumatic ones use compressed air, and battery-powered guns offer convenience. Each type serves specific needs, providing options for various caulking projects.

Ratchet Style

Ratchet-style caulk guns offer incremental dispensing of caulk. They allow for precise control over the flow, making them popular among professionals and DIY enthusiasts. This design provides ease of use and versatility for various caulking projects.

Dripless Caulk Guns

Among the types of caulking guns is the dripless caulking gun. This type is designed to minimize mess by automatically retracting the caulk when pressure on the trigger is released. Dripless caulking guns are particularly useful for clean and precise caulking applications, reducing waste and saving time.

Battery Powered or Pneumatic

When it comes to caulking guns, the choice often boils down to battery-powered or pneumatic options. Battery-powered guns offer cordless convenience, while pneumatic ones deliver consistent pressure with compressed air. Consider the scale of your project before deciding which type suits your needs best.

Put Hole In Bottom Of Caulk Tube

One reason a caulk gun might be hard to squeeze is if there’s a hole in the bottom of the caulk tube. This hole can disrupt the flow of caulk, causing resistance when trying to squeeze the trigger. It’s important to check the tube for any punctures or damage before use to avoid this issue.

When a hole is present, caulk can leak out, creating a mess and reducing the amount of caulk available for application. This not only makes it harder to control the flow but also wastes caulk. To prevent this, inspect the caulk tube carefully and replace it if there are any holes or damage detected.

Caulking Gun Trigger Mechanism

The caulking gun’s trigger mechanism can contribute to difficulties in squeezing. Sometimes, the trigger gets jammed due to dried caulk inside the mechanism. This blockage can make it hard to apply consistent pressure when using the gun.

If the trigger spring is worn out or misaligned, it can increase resistance. Regular maintenance and cleaning of the trigger mechanism can help prevent these issues. Proper lubrication can also ensure smooth operation. Checking the trigger mechanism before each use can save time and frustration during caulking projects.

Frequently Asked Questions

Why is my caulk gun not pushing out the caulk?

Your caulk gun might not be pushing out the caulk due to dried caulk blocking the nozzle or a jammed trigger mechanism. Try cleaning the nozzle and inspecting the trigger mechanism for any obstructions.

Is a caulking gun hard to use?

A caulking gun can be challenging for beginners, but with practice, it becomes easier to control the flow of caulk effectively.

How do you make caulking easier?

To make caulking easier, ensure the caulk is at room temperature and use a caulking gun with a comfortable grip. Practice steady, even pressure while applying the caulk for smoother results.

Conclusion

A caulk gun that is suddenly difficult to squeeze can leave your projects at a standstill. Check for dried caulk clogging the tip first and clear it out. Then ensure the caulk tube isn’t low or expired before trying to lubricate the rod. Getting a smooth motion back takes some troubleshooting first.

With some maintenance and awareness of what causes issues, a caulk gun can go back to smoothly dispensing caulk with an easy squeeze. Taking time to prevent dried caulk accumulation, seal air exposure on tubes, and lubricate the mechanisms will prevent frustrating jams mid-project in the future.