Furring strips are wooden or plastic boards installed under metal roofing to create an air gap. This levels an uneven roof deck and provides ventilation, allowing moisture to escape instead of getting trapped, preventing leaks and rust.

Why put furring strips under metal roofing? Metal roofs need a smooth base. Furring strips lift the roofing up. This creates an air space that allows airflow. Airflow prevents moisture buildup. Trapped moisture causes leaks or rust. So furring strips protect metal roofs.

Furring strips under metal roofing create a gap for airflow, preventing moisture traps that can lead to leaks or rust. This airflow is crucial for maintaining proper conditions and preventing issues like the metal roof affecting cell service.

Key Takeaway

- Create air gap for airflow

- Prevent moisture buildup

- Stop leaks and rust

- Level uneven roof surface

- Enable proper water runoff

- Keep metal roof dry and smooth

- Improve durability

Benefits Of Using Furring Strips Under Metal Roofing

Furring strips, also known as purlins or battens, are commonly used underneath metal roofing for various benefits.

Ventilation: Furring strips create a small airspace between the metal roofing and the underlying surface (typically the roof deck or insulation). This airspace allows for ventilation, which helps to prevent moisture buildup and reduces the risk of condensation inside the roofing system. This is particularly important in climates with high humidity levels.

Thermal Regulation: The airspace created by furring strips also acts as a thermal break, helping to reduce heat transfer between the metal roofing and the underlying structure. This can contribute to improved energy efficiency by reducing heat gain in hot climates and heat loss in cold climates.

Reduced Noise: Metal roofing can sometimes amplify noise from rain, hail, or other sources. Furring strips provide a cushioning effect that helps to dampen sound transmission, resulting in a quieter interior environment.

Improved Drainage: Furring strips can be installed with a slight slope to promote drainage, allowing water to flow off the roof more efficiently. This helps to prevent water pooling and reduces the risk of leaks or water damage.

Enhanced Fastening: Furring strips provide a solid base for fastening the metal roofing panels securely. This helps to prevent uplift in windy conditions and ensures the long-term stability and durability of the roof.

Alignment and Straightening: Furring strips can help to ensure proper alignment and spacing of metal roofing panels, resulting in a neater and more uniform appearance. They also provide a surface for attaching trim and flashing details, which helps to maintain the integrity of the roof system.

Types Of Furring Strips For Metal Roofing

| Type of Furring Strip | Description |

|---|---|

| Wood Furring Strips | Typically made from treated lumber or hardwood, used for providing a level surface and ventilation beneath metal roofing. |

| Metal Furring Strips | Made from galvanized steel or aluminum, these strips are durable and resistant to rust, often used for commercial applications or in areas prone to high moisture. |

Furring strips for metal roofing are essential for creating a level and stable surface for the metal panels to be installed onto. There are several types of furring strips commonly used in metal roofing installations.

Wooden Furring Strips: These are typically made of pressure-treated lumber or other rot-resistant wood species. Wooden furring strips are cost-effective and easy to work with. They provide a solid base for attaching the metal roofing panels.

Metal Furring Strips: These are typically made of galvanized steel or aluminum. Metal furring strips offer excellent durability and resistance to corrosion, making them suitable for outdoor applications. They come in various profiles and sizes to accommodate different roofing systems.

Composite Furring Strips: These are made of a combination of materials such as wood fibers and plastic polymers. Composite furring strips offer the advantages of both wood and metal, including durability, resistance to rot and corrosion, and ease of installation.

Foam Furring Strips: These strips are made of rigid foam insulation material. Furring strips provide thermal insulation and can help reduce energy costs by creating a thermal break between the metal roofing and the underlying structure. They are often used in cold climates to prevent condensation and heat loss.

Adjustable Furring Strips: These furring strips come with adjustable features, allowing for fine-tuning of the roof’s slope or alignment. They are particularly useful in situations where the underlying structure is not perfectly level or where precise adjustments are needed for drainage purposes.

Installation Process For Furring Strips Under Metal Roofing

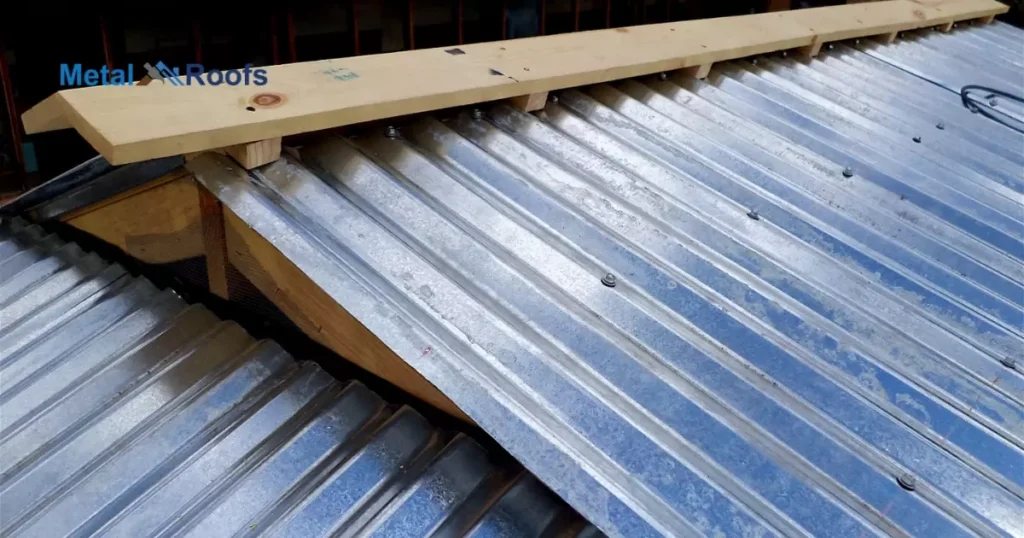

When installing furring strips under metal roofing, start by measuring and marking the locations for the strips on the roof deck. Use a level to ensure they are placed evenly. Next, attach the furring strips perpendicular to the roof rafters using screws or nails. Make sure they are securely fastened to provide proper support for the metal panels.

Once the furring strips are in place, you can begin installing the metal roofing panels. Start at one end of the roof and work your way across, overlapping each panel slightly to ensure a watertight seal. Use roofing screws to secure the panels to the furring strips, making sure to drive them into the raised ridges of the panels.

Materials And Tools Required For Installing Furring Strips Under Metal Roofing

To install furring strips under metal roofing, you’ll need some essential materials and tools. First, gather your materials: furring strips, corrosion-resistant screws, and a drill with the appropriate bit. Make sure the furring strips are straight and free from defects to ensure a level surface.

Next, prepare your tools: a tape measure, a chalk line, and a circular saw or handsaw for cutting the furring strips to length. Measure and mark the spacing for the furring strips according to the manufacturer’s recommendations, typically around 16 to 24 inches apart. Then, using the drill, attach the furring strips to the roof deck securely with screws, ensuring they are level and aligned.

Ensuring Proper Ventilation With Furring Strips And Metal Roofing

Furring strips are vital for ensuring proper ventilation with metal roofing. They create a gap between the roof and the metal panels. This gap allows air to circulate, preventing moisture buildup and mold.

Furring strips provide a level surface for the metal panels. This ensures a secure and uniform installation. With proper ventilation, metal roofing lasts longer and performs better. It also helps in reducing noise from rain or hail. Overall, furring strips are essential for maximizing the benefits of metal roofing.

Preventing Condensation With Furring Strips And Metal Roofing

Furring strips under metal roofing prevent condensation. They create a gap between the metal and the roof deck. This gap allows moisture to drain away. Without furring strips, condensation could damage the roof.

Condensation forms when warm air meets a cold surface. Metal roofing can get cold. Furring strips act as a barrier. They help to keep the metal from touching the roof deck directly. Thus, condensation is reduced, prolonging the life of the roof.

Furring Strips Spacing Guidelines For Metal Roofing

When installing metal roofing, follow furring strips spacing guidelines closely. Place furring strips at regular intervals across the roof deck. Ensure spacing between strips is uniform, typically between 16 to 24 inches apart.

This spacing provides adequate support for the metal panels. Additionally, it promotes proper ventilation and helps prevent moisture buildup. Following these guidelines ensures a sturdy and long-lasting metal roof. Proper installation enhances performance and durability.

Impact Of Furring Strips On Metal Roofing Warranty

Adding furring strips beneath metal roofing can affect the warranty. Manufacturers often specify installation guidelines to maintain warranty coverage. Improper installation, such as omitting furring strips, might void the warranty. Furring strips facilitate proper ventilation and prevent condensation, crucial for the roof’s longevity.

They also ensure a level surface for the metal panels, reducing the risk of damage or leaks. Thus, adhering to manufacturer guidelines regarding furring strips can safeguard your metal roofing warranty.

Common Mistakes To Avoid When Using Furring Strips With Metal Roofing

When using furring strips with metal roofing, avoiding common mistakes is crucial. Firstly, ensure proper ventilation by spacing the furring strips evenly to prevent moisture buildup and mold. Secondly, avoid skipping the use of a moisture barrier between the strips and the roof deck to prevent condensation issues.

Make sure the surface is level before installing the metal panels to prevent distortion. Finally, don’t overlook the importance of noise reduction by installing insulation between the strips and the roof deck. Avoiding these mistakes, you can ensure a successful and long-lasting metal roofing installation.

Cost Considerations For Furring Strips And Metal Roofing

When planning a metal roofing project, it’s essential to factor in the cost of furring strips. Furring strips create a ventilated space beneath the metal panels, aiding in moisture control and prolonging the roof’s lifespan. These strips come with an additional expense beyond just the metal roofing material.

Before proceeding, consider the overall budget and compare quotes from different suppliers for both the metal roofing and the necessary furring strips. Evaluate the long-term benefits of using furring strips, such as improved ventilation and reduced risk of condensation-related damage, to determine if the investment aligns with your priorities and financial constraints.

Longevity And Durability Of Metal Roofing With Furring Strips

Furring strips enhance the longevity of metal roofing. They create a gap, aiding ventilation and reducing moisture, which prevents mold and rot. With this barrier, condensation is minimized, preserving the roof’s integrity. The strips ensure the metal panels align evenly, preventing warping and distortion.

Metal roofing with furring strips boasts durability. The strips provide a stable base, enhancing the roof’s structural integrity. Mitigating moisture, they prevent corrosion and rust, extending the roof’s lifespan. The alignment they offer ensures the panels stay secure against harsh weather.

Insulation Benefits Of Furring Strips Under Metal Roofing

Furring strips are thin strips of wood or metal that are often used as spacers or supports underneath a surface material like metal roofing. When installed under metal roofing, furring strips can provide several insulation benefits.

Air Circulation: Furring strips create a small air gap between the metal roofing and the roof deck. This air gap allows for ventilation and airflow, which can help regulate temperatures and reduce the risk of condensation buildup. Condensation can lead to moisture issues, mold growth, and even damage to the roofing material over time.

Thermal Break: The furring strips act as a thermal break between the metal roofing and the roof deck. This can help reduce heat transfer from the exterior to the interior of the building during hot weather and vice versa during cold weather. Minimizing heat transfer, furring strips can contribute to improved energy efficiency and comfort inside the building.

Reduced Noise: Metal roofing can sometimes amplify noise from rain, hail, or other sources. The presence of furring strips can help dampen this noise by providing an additional layer of material between the metal roofing and the roof deck. This can result in a quieter indoor environment, especially during heavy rainfall or windy conditions.

Improved Installation: Furring strips provide a level surface for the installation of metal roofing panels. They can help compensate for minor irregularities in the roof deck and ensure that the metal roofing is installed evenly and securely. Furring strips can simplify the installation process by providing a framework to which the metal roofing panels can be easily attached.

Environmental Impact Of Furring Strips In Metal Roofing Applications

Furring strips play a crucial role in metal roofing applications, but their use does have environmental implications. These strips often require wood or other materials, leading to potential deforestation and resource depletion. The production and transportation of these materials can contribute to carbon emissions, further impacting the environment.

When considering the environmental impact, it’s important to weigh the benefits against the drawbacks. Furring strips can enhance ventilation, reduce condensation, and provide a level surface for metal roofing installation, ultimately improving the longevity and performance of the roof.

Frequently Asked Questions

What size furring strips for metal roof?

A metal roof, opt for 1×3 or 1×4 furring strips. These sizes offer ample support and ventilation without excess weight. Proper spacing and alignment are key for a sturdy roof.

Do you need wood under a metal roof?

Yes, you need wood under a metal roof. Furring strips provide ventilation, prevent condensation, and align the surface for proper installation. They also reduce noise and enhance the roof’s durability and lifespan.

Are furring strips necessary for metal roof?

Yes, furring strips are necessary for metal roofs. They provide ventilation, prevent condensation, ensure surface alignment, and reduce noise. These benefits improve the roof’s performance and longevity.

Conclusion

Furring strips are an important component for metal roofs. They create an air gap between the roof and deck. This gap allows air to flow. Proper airflow prevents moisture buildup. Trapped moisture leads to leaks or rust. So the air gap protects the roof. Installing furring strips levels out the deck. The strips create a smooth, consistent base.

In summary, furring strips protect metal roofs. They create space for airflow. They also create a smooth surface. Smoothness enables good water runoff. Combined, these effects prevent moisture issues. The result is a drier, longer lasting roof. Furring strips are a simple addition. But they make a big difference for durability.